Post Time:Jan 06,2013Classify:Industry NewsView:350

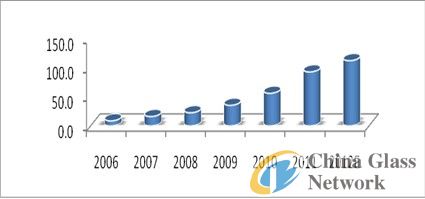

In the world, the development of the Low-E glass industry is closely related to countries’ policy support for energy efficiency of buildings. In Europe and America, the penetration rate of the Low-E glass has quickly climbed to more than 85% over seven recent years under the support of policies. At present, China is following this route. In 2011, Chinese Low-E glass industry maintained a strong momentum, and the annual Low-E glass output reached 87 million square meters, up 38% from a year earlier. However, China’s demand for Low-E glass was high up to 92.7 million square meters in 2011, thus still remaining a supply gap. In May, 2012, China's "Twelfth Five-year Building Energy-saving Plan” was introduced, an engine for the evolution of the Low-E glass industry.

In 2011, as many production lines were completed and put into operation successively, China’s Low-E glass capacity grew rapidly and the annual capacity broke through 100 million square meters. Meanwhile, there were about 20 Low-E production lines under construction, most with a designed capacity of above 2 million square meters, while the largest production line boasted the capacity of 10 million square meters per year.

In H1 2012, the development of online Low-E glass speeds up apparently. Among the new production lines, the number of the ones with the capacity of 10 million square meters per annum keeps growing, and they tend to be the new investment hot spots.

Currently, the Low-E glass production technology and equipment are mainly imported from Europe, the United States, Japan and other nations, which to a certain extent cause the manufacturing costs of Chinese Low-E glass to rise. To break the technical bottleneck, some Chinese enterprises have built more than a dozen production lines independently, conducted considerable production tests, and achieved some results.

The report makes a detailed market analysis on global and China Low-E glass industry. As for companies, this report studies four multinational corporations (PPG Industries, NSG, AGC, and Saint-Gobain) and 13 Chinese companies (including CSG, TGI, Xinyi Glass, and Yaohua Pilkington).

In 2011, in order to maintain its position as a giant, CSG made efforts to expand capacity and seize market share. It is estimated that its annual Low-E glass capacity will reach 29.4 million square meters in 2013.

In 2011, TGI accelerated the pace of capacity expansion. The company’s designed annual capacity was 36 million square meters, and it outperformed CSG to become a new leader. At present, TGI has five production lines under construction, of which the projects in Xianyang and Fengyang are both online Low-E glass production lines with the respective annual capacity of 10 million square meters, becoming Asia's largest ones.

In 2011, the Tianjin-based project of Xinyi Glass was successfully completed, the newly-added capacity was 4 million square meters, the designed capacity was 31.8 million square meters, and the actual capacity was about 16 million square meters.

Source: http://www.reportbus.comAuthor: shangyi

PrevHow has the glass industry contribute to soil pollution?

Price of Float Glass Sheet on January 6, 2013 from China Glass NetworkNext