Post Time:Aug 20,2014Classify:Company NewsView:608

Dip-Tech, the world's leading provider of digital ceramic in-glass printing solutions, will present its comprehensive offering in Las Vegas at GlassBuild America (GBA) 2014. Dip-Tech's end-to-end solution includes field-proven digital in-glass printers, digital ceramic inks, design-to-glass software for advanced image processing and sales and marketing tools and strategies.

This complete solution ensures exceptional printing results for multiple applications, enables optimal printer productivity and a proven approach to market immersion. In addition, Dip-Tech will showcase its most recent ink innovations, including two new high-performance functional inks.

Live demos of digital ceramic in-glass printing

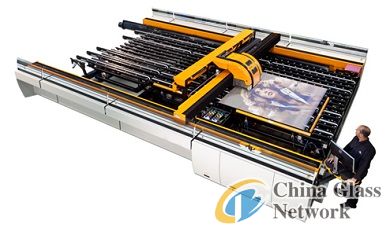

At the Dip-Tech booth (2717), visitors will be able to see the NEW Dip-Tech AR4000 printing throughout the show. Visitors are also invited to attend moderated technology and printing demonstrations on September 9th and 10th at 2:00 pm.

Express Learning Presentation

"Sold on decorative design, new products and applications for decorative glass" is an additional learning opportunity for GBA attendees. This 20 minute session will be hosted by Cathie Saroka, Marketing Director of Goldray Industries, on Wednesday, September 10th at 1:30 PM.

Like all Dip-Tech AR Series digital ceramic in-glass printers, the AR4000 delivers high throughput, high resolution, high versatility and is ideal for exterior and interior architectural and transportation glass applications. Offering unmatched print quality on glass up to 130 x 236 inches, the Dip-Tech AR Series prints up to 720 dpi with micro-drop precision.

Drop fixation, achieved through targeted heating of the glass before and after ink jetting enables higher definition images. The glass panels are held stationary during printing, for optimized ink drop accuracy and repeatability for sophisticated double sided vision applications without multiple registrations. An optional inline dryer saves costs, time, space, and optimizes print quality and precision.

Displays of newest functional inks

At the Dip-Tech booth, visitors will also be able to browse an extensive library of glass samples that demonstrate the multiple applications of Dip-Tech's wide range of digital ceramic inks for glass. These include the recently launched Dip-Tech Extra Durable S1* inks, designed for digital printing on the external side of glass surfaces. Another new ink, Dip-Tech Slip-Resistance ink, is a unique, patented ink with an etched glass-like appearance that is used to create anti-slip surfaces when wet or dry, making it ideal for exterior and interior flooring applications.

"Our field-proven Dip-Tech digital ceramic in-glass printing solution combines the durability of our ceramic inks with the versatility and quality of digital printing," said Alysa Hoffmeister, VP & General Manager of Dip-Tech, Inc. "This enables glass processors to offer a one-stop-shop for a wide range of unique printed glass applications to gain a competitive edge, accelerate business growth, and increase revenue.

Source: Author: shangyi