Post Time:Jan 05,2015Classify:Industry NewsView:535

Large float-glass manufacturers have decided to expand their production capacities to make the most of the sector's double-digit growth in the past five years.

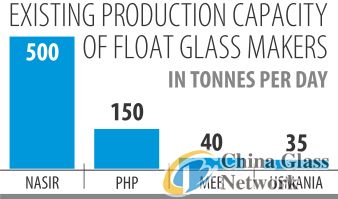

For instance, Nasir Group, which has a 70 percent market share, is setting up its second manufacturing unit for nearly Tk 1,200 crore, while PHP Float Glass, which occupies the second spot, has also planned to double its production capacity to 300 tonnes per day.

“Rising demand from outside of Dhaka and the rural areas has led us to build a second glass factory,” said Nasiruddin Biswas, chairman and managing director of Nasir Group, a conglomerate.

The float glass market, which is now worth about Tk 15,000 crore a year, is relatively new in the country. Before Nasir Group and PHP entered the market, in 2005 and 2006 respectively, the product was imported on a small scale.

The float glass market, which is now worth about Tk 15,000 crore a year, is relatively new in the country. Before Nasir Group and PHP entered the market, in 2005 and 2006 respectively, the product was imported on a small scale.

The demand for float glass, chiefly used in buildings, now stands at around 15,000 tonnes per month, which ten years ago was just 200 tonnes. And in the next five years, the monthly demand is expected to rise to 30,000 tonnes.

“Our forecast says the market will double in the next five years, mainly because of growing rural consumers,” said Biswas.

Between 2005 and 2013, the demand was driven by urban consumers, but of late, it is being fuelled by rural consumers, who now prefer the low-cost float glass to the costly wood in their houses.

For instance, 60 percent of Nasir Group's float glass is now consumed outside of Dhaka, including rural Bangladesh. It was around 10-15 percent five years ago.

Nasir Group's new factory, which will be located in Mirzapur, Tangail, will produce 800 tonnes per day, once it starts commercial production in about three years' time.

Its existing factory in Gazipur also saw its production capacity double recently to 500 tonnes per day.

“We have also planned to double our capacity to strengthen our foothold in the market,” said Mohammed Iqbal Hossain Chowdhury, managing director of PHP Family.

The scarcity of gas though is turning out to be a big headache for float glass makers, he said.

Silica and gas, the primary needs of float glass makers, are available in the country, while the secondary raw materials such as dolomite, feldspar and limestone are imported from neighbouring Bhutan, Nepal and India.

Source: http://www.thedailystar.net/business/float-glass-mAuthor: shangyi