Post Time:Aug 11,2015Classify:Company NewsView:1034

The world is facing radical changes in society. While digitization already impacts our every day life, smart-technologies are not only conquering the energy supply, transport sector and our homes, but also industrial production.

In the long run, standardized mass production and obsolete manufacturing systems will be replaced by customized and more efficient production.

In tomorrow’s smart factory, man and machine will work hand in hand supported by intelligent mobile assistance systems and real-time analysis of product and machinery data. Errors can be detected early on and eliminated before they even occur allowing for a flexible network of man, machines and products.

One step ahead, Grenzebach has developed the necessary prerequisites for Industry 4.0 (Smart Factory) and is already offering automated solutions featuring cross-system control and networking.

Glass inspection solutions, production calculation and planning tools as well as process and control know-how enable machines and robots to interact and communicate establishing a self-learning system.

Grenzebach visual inspection and measurement: Glass manufacturers are facing growing demands which require fully stable production processes that can only be met by highly developed quality and process control systems.

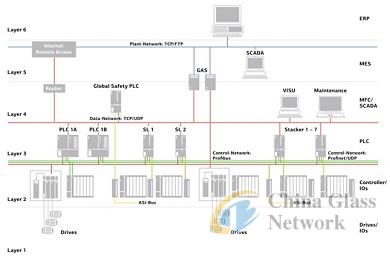

Data handling presents a specific challenge and is one of the main tasks when it comes to data collection, storage and processing alongside data security within the internal corporate network as well as the global data management.

Exceeding machinery and system limits, the network with all participants becomes the central element which requires a suitable infrastructure as well as customized security.

The Grenzebach Application Server (GAS) becomes the solution for integration of customized components and processes.

For Grenzebach customers equipment availability always comes first. In order to ensure availabilty, industrial networks are especially important.

Grenzebach Secure Plant

While projecting the first IP address, a holistic concept covering service and remote access is established to ensure a seamless integration and grant the highest possible security through intelligent combination of IT standards and devices.

Modular and scalable concepts designed by Grenzebach allow for individual solutions to meet security, price and functionality requirements.

Grenzebach Secure Plant features a holistic concept to ensure IT security of the equipment while a network security check aims to close any security gaps. The concept exists due to intelligent combination of standard technologies, such as VLAN, Firewall, coding, system hardening and visualization.

Grenzebach Maintenance Server

The Grenzebach Maintenance Server ensures central and up-to-date access to all equipment related documents and program levels of controls and HMI which is granted through projection tools. The system which is linked to the Grenzebach Control Net allows for online access to the HMI application. Grenzebach offers an automated data update through the Grenzebach Service via remote access. Due to the wide range of functionalities, the Grenzebach Maintenance Server is an ideal tool for coordination of service and repair works eliminating erros and malfunctions. Furthermore, the server offers a central back-up feature of all equipment related data.

Digitization, networking and IT security create the requirements for intelligent factories. Thus, the smart factory not only offers more flexibility, but also a much higher level of resistance against outer influences.

Tomorrow‘s customized, intelligent factory only produces what is really needed. Individual products are manufactured at the cost of mass production facilitating optimal use of resources and creating new levels of efficiency.

Grenzebach implements the vision of the intelligent factory to equip their customers for future challenges.

About the author:

Christian Herfert

Director, Business Development

Research and Development

Source: Grenzebach Maschinenbau GmbHAuthor: shangyi