Post Time:Aug 23,2016Classify:Industry NewsView:1232

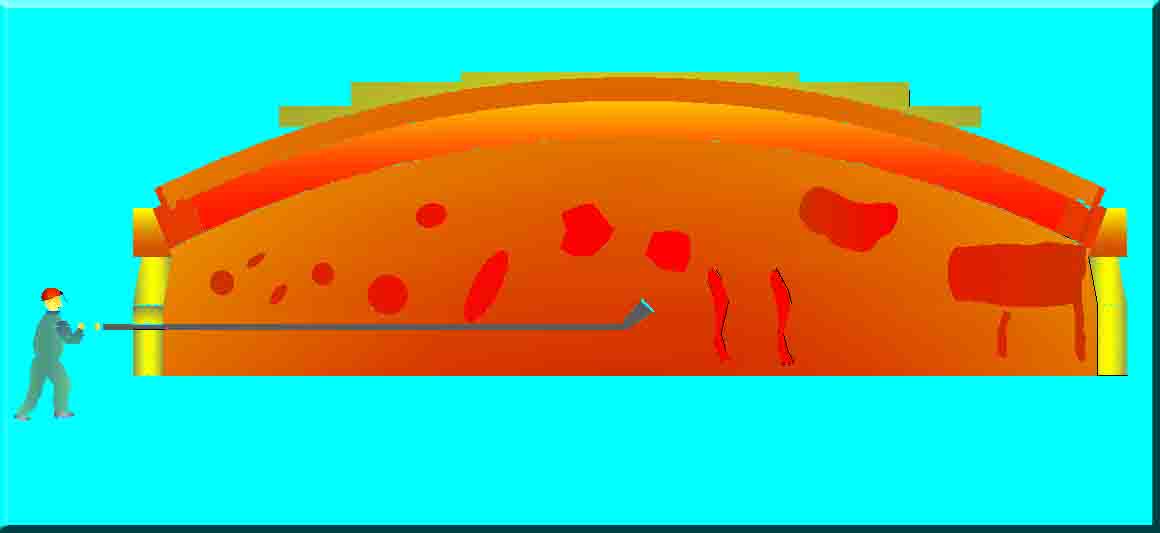

The surface of the hanging wall of float glass furnace inlet was eroded by complex gases inside the furnace, a large molten hole and a penetrating seam were caused and the whole wall was displaced downward seriously, which endangered the structure of the furnace. By using the company’s ceramic welding technology combined with the high temperature furnaces periscope, the melted hole and penetrating seam on the hanging wall were filled tightly and the repaired part maintained in safe operation for 25 months.

Source: Teng Wang Ceramic Welding Co.,LtdAuthor: Teng Wang Ceramic Welding Co.,Ltd

PrevFocus on TechHi Glass’s Presence at Glasstec 2016 in Dusseldorf

Corning Showcases Advanced Glass Innovations at Touch Taiwan 2016Next