Post Time:Aug 23,2016Classify:Industry NewsView:1245

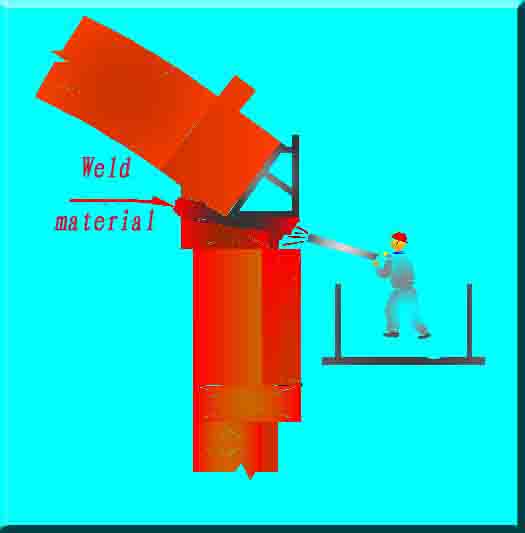

Upper clearance on chauffer 1 # ~ 5 # at the south and north side of the crown of the melting furnace of the floating glass production line which had been operating for 9 years, created partial deformation due to furnace design and temperature change, resulting in erosion at different degrees and serious burn-out and forming irregular triangular defects along the inclined arch about 80mm~100mm wide and 45 ° ~ 60 °, therefore the local temperature in the furnace was overly high, and the flame soared from the furnace and burnt the skewback beam, seriously threatening the safety of the furnace structure. By adopting the ceramic welding technology of our company, the leakage on the furnace was filled firmly and the service life of the furnace was effectively prolonged.

Source: Teng Wang Ceramic Welding Co.,LtdAuthor: Teng Wang Ceramic Welding Co.,Ltd

PrevFocus on TechHi Glass’s Presence at Glasstec 2016 in Dusseldorf

Corning Showcases Advanced Glass Innovations at Touch Taiwan 2016Next