Post Time:Aug 23,2016Classify:Industry NewsView:1495

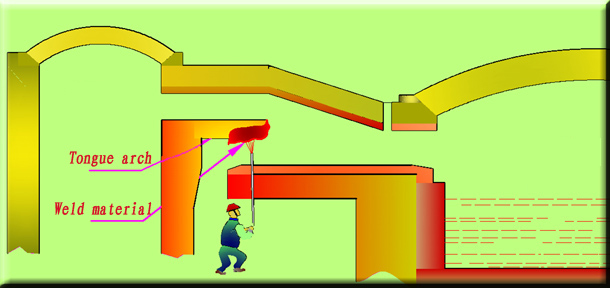

Subject to temperature change and scouring of high temperature air flow, the first ring of skewback of the tongue arch of the chauffer fell off entirely, so that gas soared into the air channel ahead of time and combustion began, which on one hand contributed to damage of the flat arch of the crater, on the other hand resulted in insufficient combustion and low combustion temperature, the heat point moved forward and the quality and output of glass was affected. The maintenance requirements are as follows: (1) welding material shall be bonded with original bricks tightly. (2) welding material itself shall be firm and resist erosion.(3) due to great temperature changes during fire exchange, the expansion coefficient of the welding material shall be similar to that of the original bricks to avoid peeling off with the original bricks after long-term use. According to these conditions, our company adopted the high temperature ceramic soldering technology combined with the high temperature furnaces periscope to repair the arch. After welding, the welding material was bonded with the original bricks firmly, and the repaired parts maintained safe operation for one year.

Source: Teng Wang Ceramic Welding Co.,LtdAuthor: Teng Wang Ceramic Welding Co.,Ltd

PrevFocus on TechHi Glass’s Presence at Glasstec 2016 in Dusseldorf

Corning Showcases Advanced Glass Innovations at Touch Taiwan 2016Next