Post Time:Nov 23,2016Classify:Company NewsView:956

GlassBuild America was the ideal platform to reconfirm the international positioning of Fenzi, a leading manufacturer of chemicals for secondary glass processing and a reference point for the industry.

All the business units of the Fenzi Group were featured at GlassBuild America 2016, the most important American event dedicated to the entire glass supply chain: mirror-backing paints, coatings for solar mirrors, decorative paints for glass, sealants and warm-edge spacers for high-performance IG unit.

The focus was also on the Tecglass machine, the most advanced digital printing tool for glass.

GlassBuild America was the ideal platform to reconfirm the international positioning of Fenzi, a leading manufacturer of chemicals for secondary glass processing and a reference point for the industry.

A key player throughout North America, it has been operating since the early eighties and in 2003 opened a production and distribution centre in Toronto.

Due to its market knowledge, wide-ranging services, ability to anticipate and meet the demands of different stakeholders, Fenzi has become a dedicated and committed partner for the entire glass industry, able to effectively meet the most various needs: from architecture to interior design, to automotive through to new energy resources relating to thermodynamic solar panels.

‘This edition of GlassBuild America has once again enabled us to develop new business opportunities with companies looking for quality products in a challenging market like the American one,” declared James Rodo, Managing Director of Fenzi North America.

“In a highly competitive environment such as America, our strength lies in the wide range of products offered, in a well-consolidated presence on the territory, and a distribution network that covers the entire United States.’

- Butylver: a P.I.B. sealant for primary sealing of IG units. Now also available in the Butylver SS versions (for flexible spacers);

- Poliver: polyurethanes engineered specifically for IG production; Poliver sealant is totally solvent free and can be used either for the production of dual seal or triseal units;

- Hotver: one component hot-melt sealant for quality IG production, ensuring perfect adhesion to the glass and spacers.

- Thiover: the world’s most widely-sold polysulphide sealant, meeting the most advanced eco-compatibility standards.

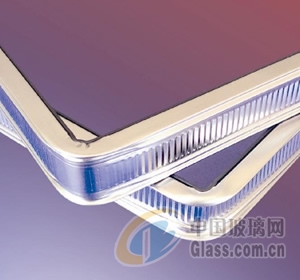

- Chromatech Plus: an innovative shape and even thinner (0.15 mm) for optimal insulating performance;

- Chromatech Ultra: stainless steel and special plastic mixes for an exclusive structure to ensure durability, strength and leading-edge insulating performance (up to 0.05 WmK);

- FGS (Flexible Glass Spacer): the innovative flexible spacer offers significant advantages in terms of precision and easy installation, especially for triple-glazed units;

- Multitech: a rigid spacer that comes in all the main widths and colors and offers the best thermal performance features that can be obtained today.

- Butylver TPS: thermoplastic spacer bar for Bystronic® applicators.

- Duralux: Mirror-backing paints available in a vast range of colors; they come in various formulations depending on the type of application and the degree of protection desired.

Duralux paints meet and exceed international quality standards, contain up to 70% less solvent, and come in zero-lead formulations.

- Duralux Solar Coatings: all the coatings in the range are engineered to ensure the highest possible chemical resistance to corrosion and to UV radiation and excellent resistance to abrasion, while at the same time offering top performance under conditions of thermal and environmental stress.

- Tempver: glass enamels for screen-printing, enameling and satin-finishing glass, strongly appreciated in the fields of architecture end interior design for the vast color range.

Two new Tempver line stand out: New Generation M, innovative enamels engineered specifically with household appliances in mind that offer improved performance in terms of application, coverage and chemical resistance, and Tempver Automotive, a line of innovative products developed for the automotive industry

- Decover: vast range of solvent- and water-based high tech paints. The applications are both large-size decorative glass sheets and custom-made glass sheets for use in interior design and in homes, offices, and stores.

Versatile yet simple and efficient tools for glass decoration, capable of printing all kinds of graphic motifs and photographic images with excellent definition and special color effects.

The Tecglass machines make it possible to use ceramic inks on sheets of any size (from a minimum of 380x380 mm to a maximum of 3,300x18,000 mm), for indoor or outdoor use, with solutions for all types of sectors and applications.

Source: www.fenzigroup.comAuthor: shangyi

PrevHow to Select Refractory Bricks for the Heating Furnace

Great minds come together for glass-focussed waste heat recovery dayNext