Post Time:Nov 25,2016Classify:Company NewsView:1137

A completely integrated software ERP solution in a modern glass processing plant is essential to achieve complete automation. Only by closing the gaps between machinery and software and by eliminating island solutions an efficient flow can be achieved.

Complete automation is making factories smarter and requires constant innovation, which is the process of making something better by use of new original ideas, mainly in software technology. Through that new form of automation software control systems are applied to reduce labour, increase raw material usage and improve quality by repeatable work methods. This process is changing the landscape of manufacturing. Modern and fully integrated software solutions furthermore coordinate the activity of the islands of automation created by the many talented machinery and system vendors. By deeply integrating and inter-connecting machinery and software in a factory a complete view of materials, status of all processes can be available to anyone, at any time.

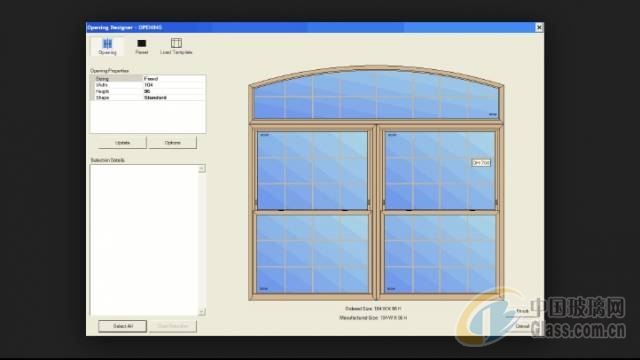

At GPD Cuba and at Cuba Glass, FeneTech will be presenting its latest release for the FeneVision MAX ERP software solution for glassmakers. This fully integrated software operates on a graphical user interface running on a single database, enabling employees to see – in real time – exactly what is happening on the production floor.

Source: www.glassonline.comAuthor: shangyi

PrevEverglade Windows is a double finalist in West London Business Awards

O-I CFO to present at the Citi 2016 Basic Materials ConferenceNext