Post Time:Nov 28,2016Classify:Industry NewsView:910

An area of growing popularity for glass usage is flooring. More designers are taking advantage of glass and incorporating it into their projects to bring more natural light and style.

The worries of strength and slips are not as prominent as advanced products that follow significant testing and standards have addressed them. All that’s left is choosing the right product for the application and the fabricator to ensure you are getting what you expect.

For the fabricator, they must ensure they are working with a product with the right properties. And they need to be aware of the standards that these products must adhere to. One such product, Walker Textures® Traction Acid-etched Anti-slip Glass, meets the criteria.

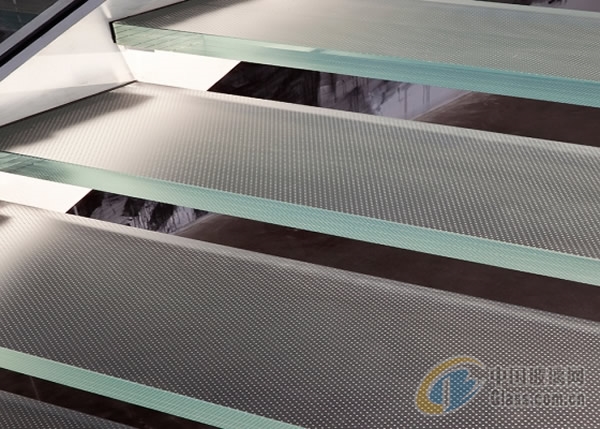

Traction is an all-glass flooring solution, using no coatings, paints or applied films susceptible to chipping or flaking off.

The slip resistant properties of Traction glass are entirely derived through acid etching, whereby portions of the glass surface are removed to varying depths by a controlled process. The Traction product line features two patterns- 406 and 407 that show unique designs and finish.

The standards that are important and now commonplace are the following:

• ASTM E2751/E2751M-13 - Standard Practice for Design and Performance of Supported Laminated Glass Walkways

• ANSI A137.1:2012 Section 9.6 - Procedure for Dynamic Coefficient of Friction (DCOF) Testing

• UL-410 - Standard for Safety for Slip Resistance of Floor Surface Materials

• ASTM F609 - Test Method for Using a Horizontal Pull Slipmeter

The key standard is the first one listed and one of the main components of it calls out why the actual glass choice is so crucial.

“Glass is a brittle material with different time and temperature-dependent properties than other solid materials used as walkways surfaces. Therefore, the type of glass is an important consideration in the design and construction of glass treads and glass landings constructed with laminated glass.”

-Significance and Use 4.1 ASTM E2751/E2751M-13

So let’s look at where the Traction product checks in at for the slip resistance side of things. Using the latest testing method of AcuTest (which uses a robotic process vs. a static one) the two patterns available in Traction bring results of 0.63 and 0.69.

Where this is significant is the threshold for this testing is 0.42. The higher the score the better.

Material choice (in this case glass) is the most important piece in the fabrication process. How the fabricator handles the product and the direction they are given by the architect all work together.

We’ve noted the need for an anti-slip material but we also need to use a product that can be successfully laminated, without defect or haze. In case of the stairwells, edges will be exposed, so the need to have post lamination edge polishing is in play.

With the edgework, comes the difference between the usages of tempered or annealed glass. There will be a different process for polishing depending on the strengthening of glass.

While many would assume tempered glass to always be the choice because of its added strength, it is not always the case.

Laminated interlayers change the prospects here, leveling that playing field and in many cases pushing the advantage towards annealed for a flatter, easier to fabricate piece. The structural design and drawings must be consulted before processing.

The other key areas of consideration are the following:

Durability- Safety is the major priority so a product that can maintain its anti-slip properties along with its structural qualities is paramount. Holding over time with those characteristics is critical.

Natural Light- One of the main reasons behind glass flooring being used is the ability to allow more natural light into the space. Studies continue to show that occupant comfort is improved by the addition of natural light.

Privacy- Because the usage of this product promotes more natural light, the location and application of this product has to be considered and the appropriate level of privacy required must be assessed.

Because Walker Textures® is meeting the above mentioned characteristics it is a solution of choice for the architectural and design community as well as glass fabricators.

Most experienced glass fabricators have familiarity with the typical acid etched product lines but may not have fabricated products specifically geared to flooring.

Choosing the right product, one with a focus on the application and tested to the industry standards is crucial.

Source: walkerglass.comAuthor: shangyi

PrevGlass Lifting at Lillie Square

Trosifol® attended CTBUH 2016 – International Conference in ChinaNext