Post Time:Oct 17,2017Classify:Industry NewsView:984

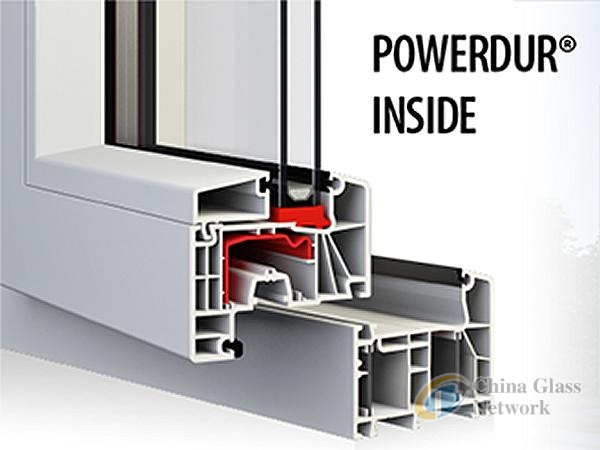

A breakthrough in the production of PVC windows! Powerdur Inside technology allows to remove the steel reinforcement from the window frame. This innovation is worth exploring!

Modern architecture requires new standards in the technical, functional and aesthetic fields. We meet the demands of our customers and we hereby introduce the completely new system - Ideal 7000 new.

Available in two versions - standard and built with the use of the innovative technology - Powerdur Inside. What's the difference? In the standard version, there is steel reinforcement applied in both in a frame and sash.

The use of "powerdur inside" technology allows to remove the reinforcement from the frame and replace it with special, thermoplastic inserts reinforced with glass-fiber Ultradur High Speed.

Inserts successfully replace steel used in conventional PVC window frames and provide an even better thermal insulation with the same mechanical properties of the window.

Windows made in the Powerdur Inside technology are a perfect solution not only in terms of their thermal insulation properties, but also in terms of installation.

Windows, at the stage of production, on request, can be fully prepared for installation, so that the time spent on the building site is reduced to a minimum. The windows are also much lighter than those with the steel reinforcement.

Ideal 7000 new system with a frame made with the use of Powerdur Inside technology is exclusively designed for application in windows.

The Ideal 7000 new system with the standard reinforcement can be applied in both windows and doors. Both solutions are characterized by a six-chamber structure of the profile and depth up to 85 mm.

The specification of the Ideal 7000 new system:

- 6 chambers (frame / sash),

- installation depth 85 mm,

- glazing up to 51 mm,

- steel reinforcement or Ultradur High Speed,

- outer sealing,

- available in a wide range of colours: smooth and wood-like.

Source: ekookna.comAuthor: shangyi