Post Time:May 17,2018Classify:VIP NewsView:1531

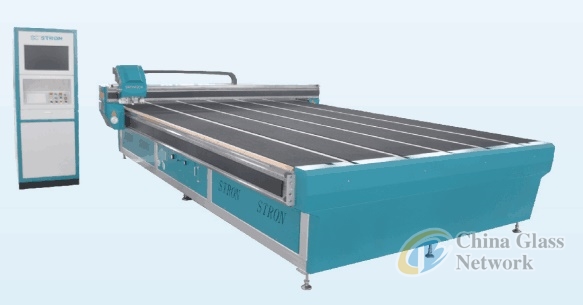

STRON is the world-renowned Glass Cutting equipment brand with leading technology in Glass Machinery industry.STRON company staff has been committed to serving glass deep-processing industry, to creating elite glass cutting products. Adhering to the company "The Machine of Quality" of corporate culture, "Excellent quality, Hundred percent service" is always in STRON staff hearts.

STRON has always been committed to maintaining a leading core technology of Glass Cutting area. and expanding an broader future space in glass deep-processing industry.Engineers maintain a high degree of rigor and innovation state, to ensure that any one STRON equipment have best precision, efficient and stability.STRON is also building the cooperate network in overseas, in America, Australia, Africa, Europe, Middle East, South Asia, we have 16 direct pr agent service network to guarantee the timely and efficient service worldwide.

STRON has developed new model: Linear Motor (Maglev) Glass Cutting Machine with higher cutting speed , better accuracy and good stability.

The Maglev Glass Cutting Machine is made of Linear Motor,Linear motor refers to a driving device which USES the principle of electromagnetism to convert electric energy directly into linear motion kinetic energy.The linear motor assures the highest cutting speed and outstanding dynamics. Maximum speed is 260m/min. Maglev Cutting Machine keep the maximum availability with maintain lower maintenance costs and lower spare parts costs.

Fixed head structure 360 degree rotation(Cutter head mechanical insurance device, in China only STRON Glass Cutting machine can use this technology), glass can be cut by any shape,automatic control of cutting pressure by SMC proportional valve to ensures accuracy of +/- 0.10 mm. OPTIMA software, cutting and optimizing software is imported with original package,guarantee a perfect performance.The automatic cutting pressure control make operation easier, especially for companies with a high variety of glass types.In addition, automatically set pressures are reported to the control system and therefore dynamic countermeasures can be taken in case of changes. Cutting oil and cutting wheel monitors show the consumption and preventively indicate a change.Stock plates are automatically sent in via the belt transport and all-automatic alignment is carried out by glass positioning aids. The XY mechanical transmission structure is composed of double linear sliding rail structure, which has stable structure and high precision.The XY mechanical motion is driven by linear motor, and the speed is high.Position detection use magnetic grating ruler (accuracy up to 1 mm) which has high accuracy and more accurate position.

Source: Stron GlassAuthor: shangyi