Post Time:Aug 13,2018Classify:Industry NewsView:1205

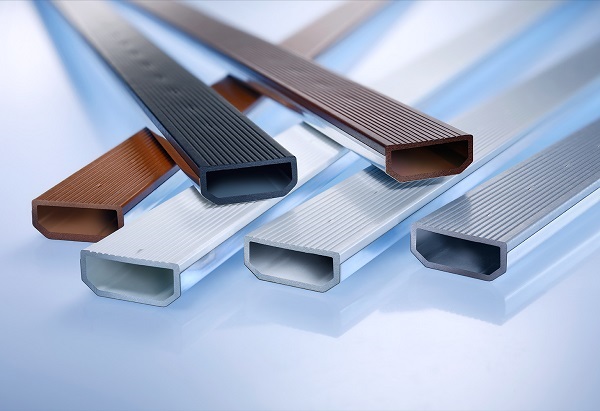

Ensinger is celebrating 25 years of Thermix – and bringing several innovations to the leading global trade fair for glass processors.1993 saw the development of Thermix, the world’s first coextruded spacer profile for the “Warm Edge”. This made it easier for insulating glass manufacturers to switch from aluminium to a thermally optimised edge bond. Within the easy-to-process and versatile Thermix range, Ensinger the plastics specialist is now further expanding the options with regard to design, performance and handling.

Façade spacer with black flank

To achieve perfect, frameless façades, Ensinger is now offering Thermix TX Pro in all sizes, also with flanks that have been printed black. These are a simple means of preventing the visual interference, known as “flashes”, that occurs as a result of stainless steel covers shining through in the edge zone of the glazing despite careful processing. Colour-fast and UV-resistant, Thermix with a black flank ensures a uniform, aesthetically convincing façade appearance.

For the most exacting standards: Thermix Low Psi

“In addition to Thermix TX Pro, with the new Thermix Low Psi we are setting standards when it comes to ease of processing and energy efficiency”, Rolf Friedrich Buhl, the Sales Director for Thermix at Ensinger, is pleased to report.

“With an impressive Psi value of just 0.029 W/mK , the Thermix Low Psi is one of the best thermally optimised spacers in the high-performance segment. This product makes it possible to optimally satisfy the most exacting standards for passive houses and ‘green building’.”

Thermix Low Psi consists of glass fibre reinforced polypropylene (PP). A multi-layer barrier film on the spacer serves as a highly efficient gas and moisture barrier and ensures the reliable adhesion of polyurethane sealant, silicone and hot-melt butyl.

Clean butyl sealing is ensured by very low product tolerances, wide flanks and accurately fitting corner connectors in the case of a sawn profile or cleanly bent corners with minimal widening in the case of a hot-bent frame.

Flex 20 for spacers and muntin bars

A flexible packaging design is now making it easier for retailers and insulating glass manufacturers to stock up on goods. Using Flex 20, 20 individually selected spacer and muntin bar variants can be assembled on a pallet as needed. Where there is limited warehousing space, a greater range of products and higher degree of processing flexibility can thereby be optimally guaranteed.

Source: www.thermix.deAuthor: Shangyi

PrevAfter Zibo Seminars, Glass Manufacturers May Accelerate Quotations Increasing Speed

Pharmaceutical Glass Tubing Market Anticipated to Grow at a Significant Pace by 2027Next