Post Time:Sep 04,2018Classify:Industry NewsView:2616

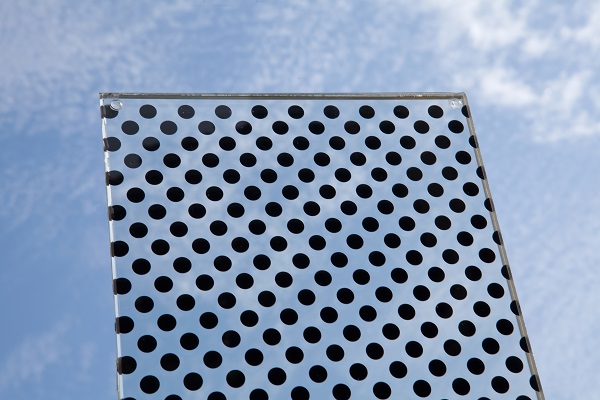

The shapes available are squares, rectangles or circles sized between two and twenty millimetres. Up to five different types can be fixed at any chosen distance on the transparent substrate that is introduced as a two-sided insert into laminated sheet glass or laminated toughened glass.

Uniform lines and grid structures are feasible as well as partial areas, graduated shades and logotypes. Elements coated on one side produce an intriguing effect. The different thermal expansion coefficients of the various surfaces produce a slight curvature in the individual shapes during the lamination process so that a three-dimensional effect is produced.

Opened in 2017 the Elbe Philharmonic Hall in Hamburg has set new standards in many ways. Its unique features are the bent, multiple coated and printed multi-purpose insulating glass sheets that produce special light effects on the building skin.

Josef Gartner GmbH, a company of the Permasteelisa-Group, clad the buildings with custom-made glass panes over a total area of 16,000 square metres. Never before had multi-functional insulating glass units been produced with a curvature along just one glass edge. To this end the glass panes were first printed, then coated and finally bent precisely according to specifications at a temperature between 500 and 600° Celsius.

Source: www.glasstec-online.comAuthor: Shangyi

PrevPrice of Chenshi Liangjie Laminating Furnace Equipment on September 4, 2018

Produce high-quality window sashes up to 300 kg reliably and quickly with “Roto AL”Next