Post Time:Sep 14,2018Classify:Company NewsView:1784

Laser film cutting and precise laminated safety glass model cutting

Technology enthusiasts will enjoy taking a look at the RapidLam model cutting machine for laminated safety glass, which has been equipped with the company’s patented laser film cutting technology as a development trial. First, the interlayer is cut by the laser integrated in the machine and then the cut contour is scored with high precision using two synchronous cutting heads. It is then a very quick job for the operator to detach the model from the sheet.

Patented technology leap in the manufacture of laminated glass and laminated safety glass

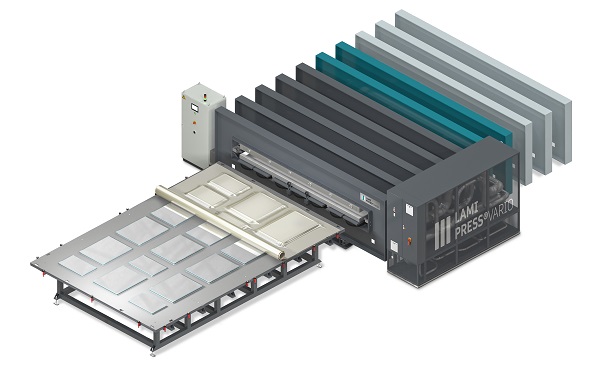

The manufacture of laminated glass and laminated safety glass also dominates the showcasing of the flatbed vacuum autoclave LamiPress that will be exhibited in collaboration with Fotoverbundglas Marl GmbH and TU Darmstadt.

With an innovative combination of positive pressure, vacuum and heat conduction, the machine is capable of processing a great variety of glass (float glass, toughened glass, tempered glass, thin glass, structured or special-purpose glass) and interlayers (PVB, SentryGlas, EVA, TPU) with short cycle times from just 40 minutes to produce high-quality and certified laminated safety glass.

LamiPress also offers flexible options for special lamination processes. The different types of interlayer, the types of glass and the laminate thickness can be mixed and combined at will within a batch.

Source: www.hegla.deAuthor: Shangyi