Post Time:Sep 29,2018Classify:Company NewsView:1288

Glass polishing is to use chemical or physical methods to remove the grain, scratch and some other defects on the surface of glass, so as to improve the transparency and refractive index of glass. Make the glass more glass. Precision and efficiency are the core of polishing technology.Physical polishing is the mechanical way of leveling the surface of an object.

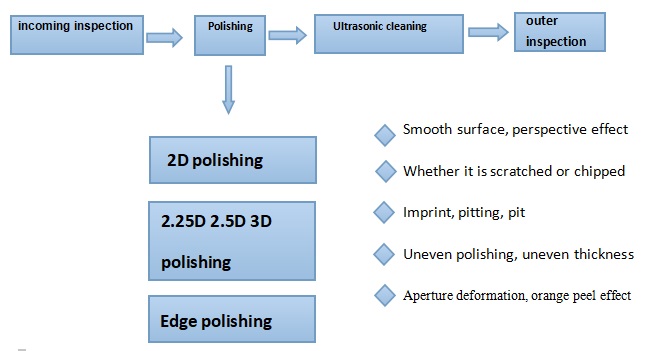

Process flow:

Matters needing attention:

1. During the polishing process, the surface of glass needs polishing powder. The polishing process and grinding process are also carried out by grinding machine.

2. After the grinding and processing, the workpiece needs to be rinsed with warm water to effectively remove the adhered rigid stone powder. Then, the workpiece is prepared for polishing in the plane polishing machine.

3. When polishing the workpiece, do not add too much polishing powder; otherwise, the polishing agent will slide, but there is no polishing effect.

4. The amount of polishing agent can be added by using automatic equipment of the machine, which needs to be defined by the polishing workers according to the test. As the degree of polishing on the surface of the workpiece is different, it can be judged whether the type of polishing agent is used correctly.

Source: Baidu EncyclopediaAuthor: Kairuiqi

PrevPrice of Tech Hi 12mm Ultra White Single Sided Frosted Glass on September 29, 2018

Schüco: Energy efficiency in vibrant colour - RAL Building, BonnNext