Post Time:Jun 24,2019Classify:Industry NewsView:3268

Laminated Glass

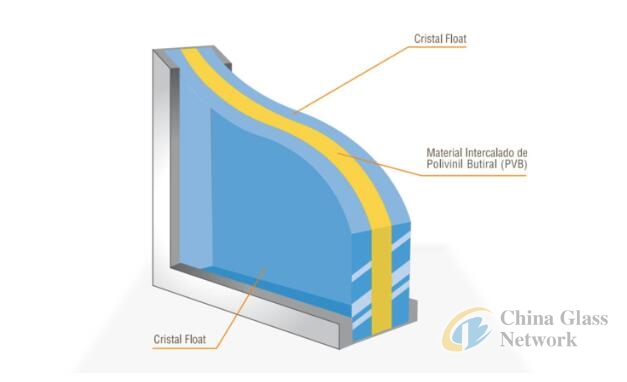

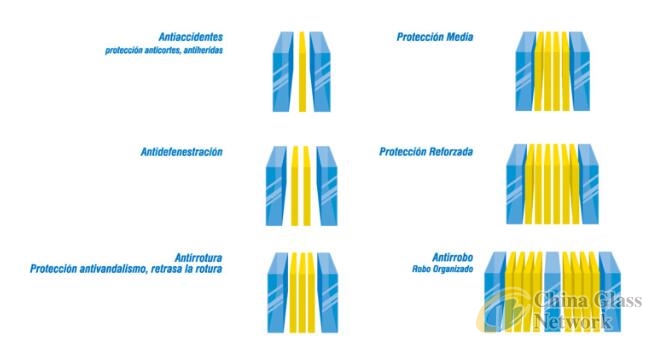

Laminate, made up of two glass panels with a plastic film between them, offers more protection against vandalism. To break through, you would have to break the first glass panel, then the plastic film, and then the second panel. This feature is especially important for skylights or other windows on the roof if you want to guarantee the security of the building's inhabitants.

Glass floors require many layers of laminate to support the weight of the people walking on them.

Tempered Glass

This glass is heavy but fragile. Thermal treatments like tempering or heat-strengthening increase glass' mechanical resistance up to 5 times that of non-treated glass. This is an excellent option for glass doors which have to withstand constant force when being opened or closed.

In buildings with high sun exposure and heat intake, there is a greater risk for breaks in their surfaces thanks to overheating. Tempered glass gives increased resistance to heat damage and high temperatures.

Solar Control and Design

Screen Printing / Digital Printing

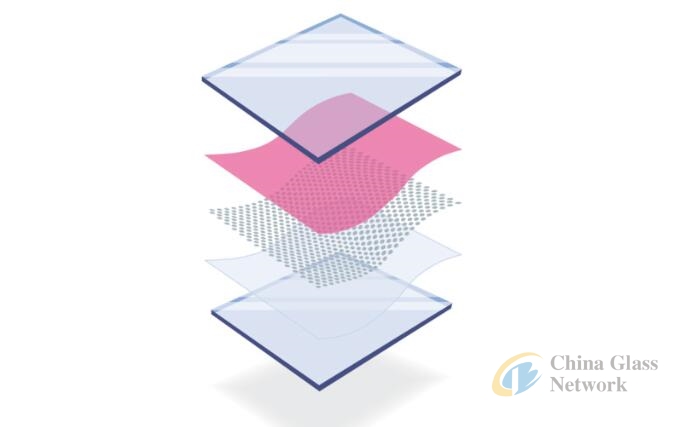

Surface printing, or digital printing, consists of applying a layer of paint that permeates the glass through heating. You can choose based on the look of the glass, like adding images, or the function, like solar performance. For example, if you add white points on the glass, this will create shade spots in the interior space.

In the case of light shafts, you can use the double point technique, painting dots over a certain percentage of the glass (for example, 50% of the surface). White dots are painted on the exterior and reflect the sunlight and prevent it from passing through while black dots painted on the interior, while blocking the sun, still allow you to see everything outside the window.

Analyzing the particulars of every project will allow you to get the most effective results from the fixtures you choose to build with. In high towers, for example, many builders opt for a mix of the previously mentioned solutions, combining Double-paned, laminated, and tempered glass.

Fire Resistant Glass / Firewall Glass

There are two types of this glass. First, you have fire resistant glass that stops the fire and the toxic gases (the principal cause of death during a fire) and then the fire wall which stops the fire, the toxic gases, and the increase in temperature. The latter acts as a barrier that absorbs the necessary percentage of heat that prevents the fire from spreading for a given amount of time (F30, F60, F90, F120).

Regulations provide guidelines for executing processes correctly, be it manufacturing a product or designing and constructing and building, and eliminate the possibility of arbitrary decisions.

In Argentina, IRAM is the regulatory body, while in Chile it's the NCH, in Europe the EN, in the US the ASTM, and so on and so forth in every country in the world. Within every regulation, there are specifications that dictate every facet of design and construction and there are even certifications for products according to international testing, such as the ANSI SGCC (for laminated glass) and IGCC (for double-paned glass).

If you are unsure of the regulations that correspond with your project, it's possible to refer to the current regulations found in Europe or the United States as a way to ensure the efficacy of the solutions you have chosen for your project. In any case, it's essential to review the technical specifications of the products you have chosen and to ensure the support of the specialists from your supply companies.

Trust in the specialists' assessment: As architects, we're not necessarily experts in glass, nor do we have reason to be. Choosing the wrong solution could have grave long-term consequences, such as excessive air conditioning costs.

Understand the project and the characteristics of the glass: Location, orientation, function, and specific hours of use, among other variables.

The bigger the glass, the wider it should be: Or, at least, it should come with the necessary treatments to ensure its mechanical resistance.

When looking at the glass' appearance, verify that the appearance won't change once it is installed: Certain conditions can alter the appearance and behavior of glass.

Dialum's plant in Santiago, Chile can process practically any type of glass on the market today and is also certified to import and work with glass of every type, coming from all over the world.

Source: https://www.archdaily.com/918008/Author: shangyi