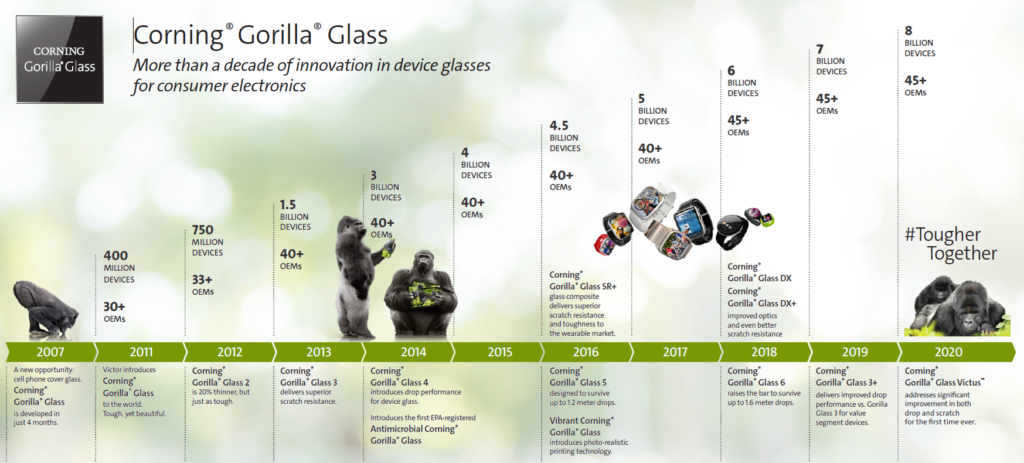

For over a decade the best mobile phones have often listed Corning Gorilla Glass front and/or back protection in their specifications and more recently wearables have used it as well.

Competitors to Corning Gorilla Glass include Asahi Glass Co’s Dragontail which has been used in models like the Pixel 3 series and some Alcatel feature phones as well as Corning’s own Ceramic Shield glass which is exclusive to iPhones.

Google Pixel 6 Pro is engineered with Corning Gorilla Glass Victus – the toughest Gorilla Glass yet which is on the front, back and camera bar of the Pixel 6 Pro, delivering significantly improved drop performance and up to 2x better scratch resistance than previous Pixel phones.

People want their phones to be tough, light, thin, scratch and drop resistant which is hard when the front of phone screen is made of glass and sometimes the back is as well.

Corning Gorilla Glass has been a key player in the smartphone world from when the iPhone first launched and Steve Jobs wanted a scratch resistant glass touchscreen.

Corning scientists have performed thousands of hours of tests to understand how and why glass breaks when dropped. And they continue to innovate by finding new ways to strengthen glass to deliver dramatically improved performance against drops on rough surfaces.

The process begins when raw materials are blended into a glass composition, which is melted and conditioned. The molten glass is fed into a trough called an “isopipe” overfilling until the glass flows evenly over both sides.

It then rejoins, or fuses, at the bottom, where it is drawn down to form a continuous sheet of flat glass that is so thin it is measured in microns. The glass is untouched by human hands or anything else that could introduce flaws into the surface.

The composition of Corning Gorilla Glass enables a deep layer of chemical strengthening through an ion-exchange process where individual glass parts are cut from the “mother sheet” and undergo an ion-exchange process.