Post Time:Apr 26,2023Classify:Company NewsView:2302

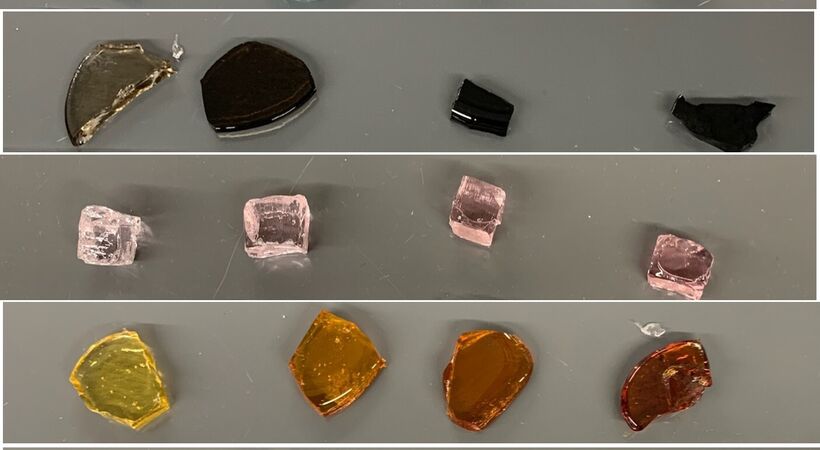

Researchers at Penn State University, USA, have created a new family of glass compositions, called Lionglass, that will help lower energy costs and extend tank lifetimes.

A glass chemistry innovation can help glass manufacturers reduce their costs as well extend their furnace production lifetimes.

Lionglass is a new family of glass chemistry developed by a team of glass researchers at Penn State University.

LionGlass is meant to replace soda lime silicate glass — the common glass used on everyday items including windows, jars and drinking glasses.

The makers of LionGlass say it can help lead to more sustainable form of glass manufacturing.

Sustainable manufacturing

Soda lime silicate accounts for the vast majority of global glass production and is therefore responsible for the greatest carbon footprint of the glass industry as a whole.

There are two contributions to its carbon footprint: the high temperatures required for melting the glass and the release of carbon dioxide as carbonate batch materials (limestone and soda ash) decompose into oxides.

LionGlass addresses both of these sources of carbon dioxide emission by eliminating the use of carbonate batch materials and by lowering the melting temperature.

The lower temperatures will also help extend the lifetime of glass melting tanks.

Prof John C. Mauro of Penn State University said: “I believe this should be a win-win situation for everyone involved.

“Glass manufacturing partners will be at the forefront of a new glass innovation that will help lower energy costs, extend tank lifetimes, improve mechanical properties, and make a major move toward sustainable manufacturing.

“Consumers and society at large will benefit from the substantially lower carbon footprint of the glass industry.”

Next steps

The next stage of the LionGlass development is to partner with a glass manufacturing partner (or multiple partners) to aid with scale-up development, customer sampling and commercialisation.

Prof Mauro said: “We don’t want LionGlass to be seen as a threat to the existing glass industry.

“We see future LionGlass collaborations as an opportunity where everyone wins: the glass companies, the consumers and, ultimately, our whole planet by driving the glass industry toward sustainable manufacturing.”

Development

The innovation has been in development for the past two years at Penn State University.

LionGlass was developed by a team of researchers within the Glass Research group at Penn State including two Ph.D. students (Matthew Mancini and Shaylee Traugh), two undergraduate students (Colleen Gallagher and Sierra Astle), a post-doctoral scholar (Nicholas Clark), and two faculty members (Jane Cook and Prof John C. Mauro).

A provisional patent application was filed on March 15, 2022, and the final application was filed one year later.

LionGlass was also presented to the industry at the GlassTrend conference in Eindhoven, the Netherlands, last week.

Source: glass-internationalAuthor: shangyi

PrevColoured PV modules with Fraunhofer ISE patent achieve market maturity

HIGH RISE - NORTHERN EXPOSURE - Top Speakers in Finland 13.6.2023Next