Post Time:Dec 11,2023Classify:Industry NewsView:1042

Thermoseal GroupPartnering with one reliable British supplier for all IGU components can prevent a host of supply chain problems, argues Thermoseal Group Sales Director Mark Hickox.

Thermoseal GroupPartnering with one reliable British supplier for all IGU components can prevent a host of supply chain problems, argues Thermoseal Group Sales Director Mark Hickox.

Slimming down your supply chain presents many opportunities for manufacturers that want a single point of contact and fewer deliveries, but the benefits actually go far beyond this, according to Thermoseal Group’s Sales Director Mark Hickox.

“Ever since we started manufacturing, we’ve been on a mission to supply the highest quality products possible,” he says. “We could just have a warehouse with a testing facility, but we still wouldn’t be able to react quickly if there was a problem, or if we wanted to react quickly to market demands.”

With four distribution warehouses around the UK, alongside two manufacturing sites, Thermoseal Group has complete control over the whole supply chain, ensuring that customers’ deadlines are met.

As well as Thermobar and Thermoflex spacer bars for IGUs, Thermoseal Group also supplies a range of other products required for the manufacture of sealed units, including corner keys, Georgian bar, desiccant, primary and secondary sealant, and cloth tape. All components are tested at the company’s laboratory before distribution, guaranteeing that they all work together effectively for a long-lasting sealed unit.

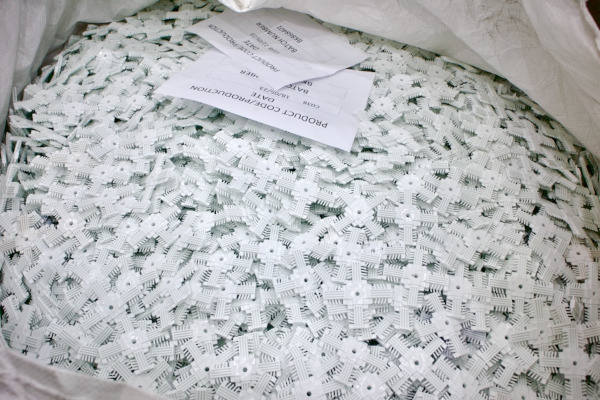

“Significantly, we can respond quickly to new demands, or where we see that there is a gap in the market,” Mark says. “For example, we have just invested in new injection moulding machines for our new Georgian Bar Anchor and Thermobar Straight Connector, both of which promise to increase efficiencies, reduce waste, and improve product quality for IGU manufacturers.”

The straight connectors and Georgian Bar Anchors are designed and engineered by Thermoseal Group to meet exacting tolerances so there is no threat to the integrity of the final unit. They are also regularly tested at the component supplier’s onsite laboratory, giving customers complete confidence in their ability to perform for the life of the unit.

“The importance of the fact that we both manufacture our own products and test them in-house cannot be understated”, Thermoseal Group’s Sales Director Mark Hickox says. “In our R&D phase, we have full control over the testing of our new products, to ensure that they not only perform well, but that they also work in perfect tandem with other products in a complete unit.

“Once they have met our testing criteria, we are then able to manufacture them to our own rigorous quality standards – guaranteeing high-performance products for our customers.”

Thermoseal Group’s new straight connector secures two lengths of Thermobar rigid spacer bar to make one continuous length, allowing customers to maximise the use of offcuts, reducing waste. This, according to Mark, will actively put money back in customers’ pockets through a higher utilisation of the product and reduced skip costs.

The new Georgian Bar Anchor comes in two designs: a stepped version for manual application, and a ridged version for securing frames into flexible spacer systems using auto-applicators. This allows Georgian bars to be connected to flexible and rigid warm edge spacer bars without using staples (thus leaving the gas barrier intact), giving a cleaner, more aesthetically pleasing finish than alternative methods.

“Units with Georgian bars slow down automated processes, especially on fully automated flexible lines,” Mark says. “With our new Georgian Bar Anchors, we can accurately match the presets of the unit line, so there is no need to stop and start. This reduces your lead times and increases your profit in the process,” Mark says.

Finally, the component supplier ships all deliveries on its own fleet of lorries, in a bid to remove any chance of product damage.

“I’ve lost count of the number of times someone has shown me the poor state other products are delivered in,” he says. “It really is shocking that all that hard work in designing and manufacturing highly technical products can be undone because a third-party carrier doesn’t care. So delivering our own products is the important final piece of the jigsaw.

“While customers may immediately see the benefit of having all goods delivered in one shipment, the main incentive for us to manage all stages of the manufacturing and supply of IGU components is quality. Yes, you can rely on us to deliver on time and in full, but you’ll also have fewer reasons to worry about failing units.”

For more information, please visit www.thermosealgroup.com, or call 0121 331 3955.

Source: Thermoseal GroupAuthor: shangyi