Post Time:Sep 24,2024Classify:Industry NewsView:1612

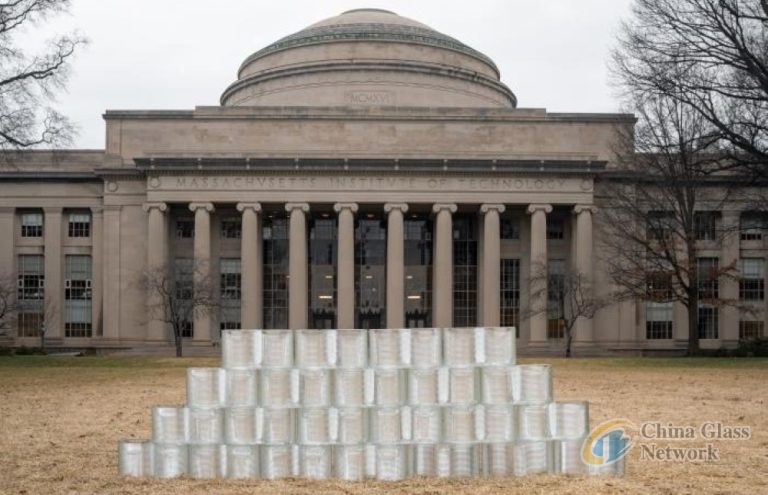

Massachusetts Institute of Technology (MIT) researchers have engineered sustainable glass bricks that could replace

current cement building blocks.

The bricks are made using 3D-printed, recycled glass, printed using MIT spinoff Evenline’s Glass 3D Printer 3 technology.

The printer was paired with a furnace to melt crushed glass into a molten form.

The researchers say each of the glass blocks is strong, multilayered and designed in a figure-eight shape to enable interlocking,

much like LEGOs. They explain that a single glass brick can withstand pressures similar to a concrete block. The hope is that the

3D-printable glass masonry could be reused repeatedly as recyclable bricks for building facades and internal walls.

“Glass is a highly recyclable material,” says Kaitlyn Becker, MIT’s assistant professor of mechanical engineering.

“We’re turning glass into masonry that, at the end of a structure’s life, can be disassembled and reassembled into

a new structure or stuck back into the printer and turned into a completely different shape. All this builds into

our idea of a sustainable, circular building material.”

In a Glass Structures and Engineering study, Becker, researcher Michael Stern and fellow co-authors describe their glass brick design.

They say the strongest glass bricks were mostly made from printed glass, with a “separately manufactured interlocking

feature attached to the bottom of the brick. These results suggest that most masonry bricks could be made from

printed glass, with an interlocking feature that could be printed, cast, or separately manufactured from a different material.”

The team aims to determine whether the brick’s interlocking feature could be made from printed glass but

does not see this as a dealbreaker to scale up the design. They aim to build progressively bigger, self-supporting glass structures.

“We have more understanding of the material’s limits and how to scale,” says Stern.

“We’re thinking of stepping stones to buildings and want to start with something like a pavilion—a temporary

structure that humans can interact with and that you could then reconfigure into a second design.

And you could imagine that these blocks could go through a lot of lives.”

Source: usglassmagAuthor: shangyi

PrevGlassBuild America 2024:The Glass, Window & Door Expo being held SEP. 30 – OCT. 2, 2024,

FEVE and Vetropack: How to get people to recycle more glassNext