Post Time:Dec 23,2024Classify:Industry NewsView:1602

Top 7 Trends in the Glass Substrate for Semiconductor Packaging Market

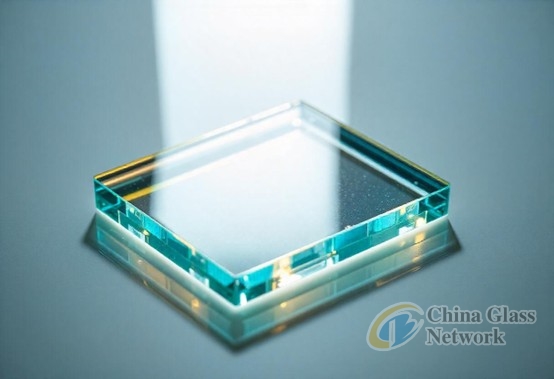

Glass substrates play a critical role in semiconductor packaging, providing a stable and reliable platform fo0r mounting semiconductor devices. As the demand for smaller, faster, and more reliable electronic devices continues to grow, the glass substrate market for semiconductor packaging is experiencing several key trends that are shaping its future. Let's explore the top seven trends in the Glass Substrate for Semiconductor Packaging Market:

Here are the Top 7 Trends In The Glass Substrate for Semiconductor Packaging Market:

Increasing Demand for Thin and Ultra-Thin Glass Substrates

Adoption of Low-temperature Co-fired Ceramic (LTCC) Substrates

Growth in Demand for Wafer-Level Packaging (WLP)

Development of Advanced Glass Formulations

Increasing Focus on Environmental Sustainability

Integration of Advanced Packaging Technologies

Focus on Cost-Effective Solutions

1. Increasing Demand for Thin and Ultra-Thin Glass Substrates

One of the key trends in the glass substrate market for semiconductor packaging is the increasing demand for thin and ultra-thin glass substrates. As electronic devices become smaller and more compact, manufacturers are seeking thinner glass substrates that can accommodate the shrinking size requirements of semiconductor packages. Thin and ultra-thin glass substrates offer advantages such as improved thermal performance, reduced weight, and increased flexibility, making them ideal for use in advanced semiconductor packaging applications.

2. Adoption of Low-temperature Co-fired Ceramic (LTCC) Substrates

Low-temperature co-fired ceramic (LTCC) substrates are gaining popularity in the semiconductor packaging market due to their excellent thermal and electrical properties. LTCC substrates offer advantages such as high thermal conductivity, low dielectric loss, and compatibility with a wide range of semiconductor devices. These substrates are particularly well-suited for high-frequency and high-power applications, making them an attractive choice for manufacturers looking to improve the performance of their semiconductor packages.

3. Growth in Demand for Wafer-Level Packaging (WLP)

Wafer-level packaging (WLP) is experiencing significant growth in demand, driving the need for advanced glass substrates that can meet the requirements of this packaging technique. WLP offers advantages such as improved thermal performance, reduced package size, and lower cost compared to traditional packaging methods. Glass substrates for WLP applications must be able to withstand the high temperatures and pressures involved in the packaging process, while also providing excellent electrical insulation and reliability.

4. Development of Advanced Glass Formulations

Manufacturers are developing advanced glass formulations that offer enhanced properties such as improved thermal conductivity, lower dielectric constant, and higher mechanical strength. These advanced glass formulations are designed to meet the evolving requirements of semiconductor packaging, providing solutions that offer superior performance and reliability. Advanced glass formulations are also being developed to address specific challenges in semiconductor packaging, such as the need for hermetic sealing and compatibility with emerging packaging technologies.

5. Increasing Focus on Environmental Sustainability

Environmental sustainability is a growing trend in the glass substrate market for semiconductor packaging, with manufacturers focusing on developing eco-friendly products. This trend includes the use of recycled materials in glass substrates, as well as the development of manufacturing processes that minimize waste and energy consumption. Manufacturers are also exploring ways to reduce the environmental impact of their products, such as by using renewable energy sources and implementing efficient recycling programs.

6. Integration of Advanced Packaging Technologies

Advanced packaging technologies such as fan-out wafer-level packaging (FOWLP) and system-in-package (SiP) are driving the need for glass substrates that can support these technologies. Glass substrates for advanced packaging applications must be able to accommodate the complex geometries and high-density interconnects required by these technologies, while also providing excellent thermal and electrical properties. Manufacturers are developing glass substrates that can meet these requirements, enabling the integration of advanced packaging technologies into semiconductor packages.

7. Focus on Cost-Effective Solutions

Cost-effectiveness is a key consideration in the glass substrate market for semiconductor packaging, with manufacturers seeking to develop solutions that offer high performance at a competitive price point. This trend has led to the development of glass substrates that offer a balance of performance, reliability, and cost-effectiveness, making them suitable for a wide range of semiconductor packaging applications. Manufacturers are also exploring new manufacturing processes and technologies that can reduce production costs and improve the overall competitiveness of glass substrates for semiconductor packaging.

Source: https://www.verifiedmarketreports.com/Author: shangyi