Machine Application

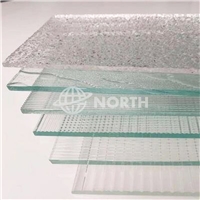

Full Automatic Flat Glass Laminating Line is a special plant used to produce the flat laminated glass, which mainly used in the fields of architecture (doors, windows), bulletproof glass, garden fence, elevator, furniture, etc.

Technical Features:

1. Water used here are automatically circulated and filtered, and the temperature of hot water can be controlled automatically.

2. Key parts in washing section are all of stainless steel, aluminium alloy and nylon materials.

3. Speed of driving system is stepless adjust.

4. Blower is installed in air cabinet with air entry filtrating net, which ensures clean drying air.

5. Low-e glass could be washed

6. The washing water adopts automatic circulation & filtration system, and the temperature of hot water is control automatically.

7. Blower is mounted in the air box with filtering mesh to clean inlet air ensuring cleanness of the drying air.

8. Air heating device make it easier to dry the raw laminated glass sheet after washed.

2. Supply Scope (main parts):

2.1. Automatic Tilting Loading table (One side one station)

2.2. Transition conveyor section I

2.3. Washing & drying machine

2.4. Transition conveyor section II

2.5. PVB film combining section (Three rolls)

2.6. Transition conveyor section III

2.7. IR Pre-heating section

2.8. Pre-pressing section

2.9. IR Heating section

2.10. Pressing section

2.11. Transition conveyor section IV

2.12. Unloading table

2.13. Control system

2.14. Technical documents

2.15. Autoclave

2.16. Ferry and Rails for autoclave

2.17. Air tank for autoclave

2.18. Cooling tower

2.19. Air compressor for autoclave

Technical Features:

1. Water used here are automatically circulated and filtered, and the temperature of hot water can be controlled automatically.

2. Key parts in washing section are all of stainless steel, aluminium alloy and nylon materials.

3. Speed of driving system is stepless adjust.

4. Blower is installed in air cabinet with air entry filtrating net, which ensures clean drying air.

5. Low-e glass could be washed

6. The washing water adopts automatic circulation & filtration system, and the temperature of hot water is control automatically.

7. Blower is mounted in the air box with filtering mesh to clean inlet air ensuring cleanness of the drying air.

8. Air heating device make it easier to dry the raw laminated glass sheet after washed.

3.1. Basic parameters

| Max. glass size | 2500x3660 mm (W x L) |

| Min. glass size | 300 x 400mm (W x L) |

| Glass Thickness (Each single sheet) | 3-19mm |

| Glass Thickness range (Total) | 6-60 mm |

| Productivity | 1-1.2M/min(take 5+5mm for example) |

| Water consumption: | 2.5m3/h(Recycling used) |

| Finished product rate | 闁?8% (5mm as sample)

|