Product Description

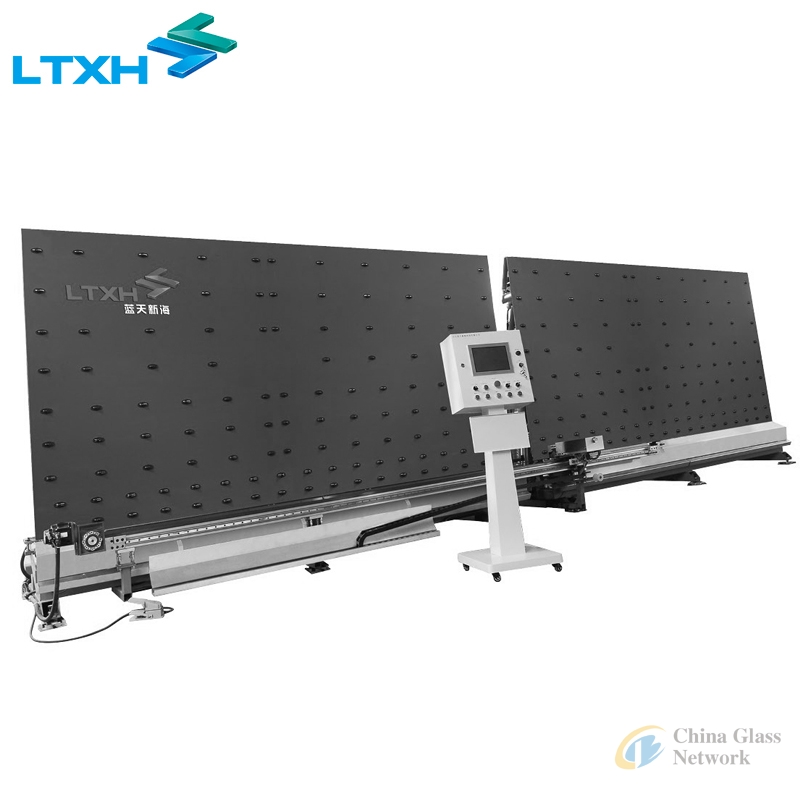

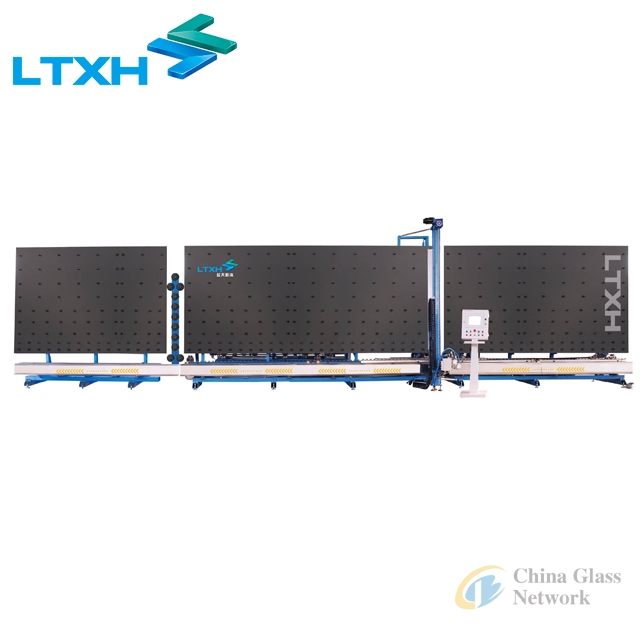

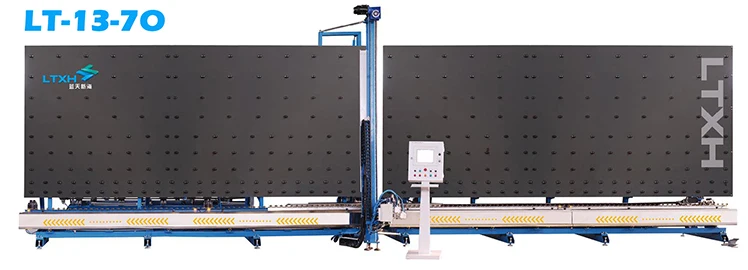

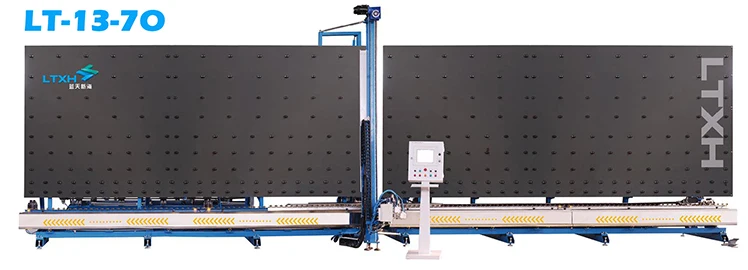

Glass SIZE 3300 x 9000 Automatic Sealing Robot

Fully Automatic Hollow Glass Sealant Sealing

| Technical Parameters |

| Min. Glass Size(mm) | 250(H) x 350(L) less 250(optional) |

| Max. Glass Size(mm) | 3300(H) x 7000(L) over 7000(optional) |

| Glass from the ground(mm) | 480-580 |

| IG Thickness (mm) | 12-50 over 50(optional) |

| Coating Speed | 5m-40m/min |

| Coating Depth | 3~28mm (optional) |

| Pressure | <32Mpa |

| Degree Angle | 6°~ 8° |

| Max. Glass Weight | 1200kg |

| Power Supply | 10kw |

| Dimension(m) | 17(L) x 3(W) x4.1(H) |

| Max. number of glass /h | 108 Pcs |

Advantages

? Quick changing glue nozzle, the burr edge and special glue mouth can be replaced within 15 seconds without tool.

? Tank transmission System, the max bearing weight is: 1 Ton, the chain life is about 10 years, the transfer block can be replaced individually,

and it has self-cleaning self-repair function.

? Two complete sealant supply (pump, mixing device) system, which can be switched freely.

? Achieve various size of rectangle insulating glass automatic continuously sealing, high efficiency & stable quality sealing performance.

? Friendly interface, easy for operation.

? The sealing of all edges and corners enriches no air bubbles, fully coating, without manual trimming.

? Synchronous belt transmission System, smooth glass delivery, accurate positioning.

? Compact layout, small footprint.

? Special glue mixer structure, easy to disassemble and clean, not easy to damage the mixed core, reduce the cost of use.

Product Comparison

| Product | LT-13-1 | LT-13-2 | LT-13-2C | LT-13-5 | LT-13-6 | LT-13-7 | LT-13-8 |

| Coating function | 3glass-2cavity | 3glass-2cavity | 3glass-2cavity | 3glass-2cavity | 3glass-2cavity | 3glass-2cavity | 3glass-2cavity |

| 2 sealant supply | 2 sealant supply | 2 sealant supply | 2 sealant supply | 2 sealant supply | 2 sealant supply | 2 sealant supply |

| Special Glass | Special Glass | Special Glass | Special Glass | Special Glass | Special Glass | Special Glass |

|

| Min Glass Size(mm) | 230×180 | 250×350 | 250×350 | 250×350 | 250×350 | 250×350 | 250×350 |

| Max Glass Size | 2000×2500 | 2500× 4000mm | 2500×4000 | 2500×5000 | 2500×6000 | 2500×7000 | 3300×8000 |

| Coating Depth | 3-18 mm | 3-28 mm | 3-28 mm | 3-28 mm | 3-28 mm | 3-28 mm | 3-28 mm |

| Max Glass Weight | 500 kg | 800 kg | 800 kg | 1000 kg | 1200 kg | 1200 kg | 3000 kg |

| Power Supply | 9 kw | 10 kw | 10 kw | 10 kw | 12 kw | 10 kw | 17 kw |

| Dimension (m) | 7.5×3× 2.7 | 10×3×3.3 | 10×3×3.3 | 11×3×3.3 | 13×3×4.1 | 15×3×4.1 | 17m×3m×4.1 |

Our Services

Pre-Sale Service

We will cooperate with every Client to achieve the best production line configuration.

Technical Support

We provide 24-hour online technical support services.

Pre-Sale Service

For long-term cooperation clients, we provide overseas technical services (local after-sales service)

LTXH- SHOW TIME

OUR PARTNERS

Top Brand Partner for the Main Parts

?Control System from Japan

?Hydraulic accessories from Taiwan China

?Sensor from Germany & Japan

?Seals from Germany & Italy

?Pneumatic parts from Japan

?Low-voltage electrical appliances from Korea

Other accessories are high quality standards that can be easily purchased from local market.

Why Choos LTXH ?

Why Choose LTXH ?

One of the biggest insulating glass coating machine manufacturer In China, providing products with top quality and good service.

LTXH strictly follows modern company management and operations regulations, setting up our own design center, quality control center and marketing service center.

We Offer OEM&ODM Service, we have our own professional designers to meet any of your requirements.

LTXH has great team with rich experience in the glass industry. Products designing and manufacturing is customer-centered in order to provide suitable products for the clients.

Company Information

BEIJING LTXH SCIENCE & TECHNOLOGY CO., LTD. | Insulating Glass Processing Solution Leader

We LTXH has been leading a complete glass processing industry since 2012 as a I.G processing solution leader in China. We are committed to employing advanced technologies with the highest level of quality, service and value to our clients.

Our core business is to design, build and operate Insulating Glass Processing line. Headquartered in Beijing, China. LTXH has branch offices in Hebei, China. Especially we are the first company who have installed the largest glass size (3,300mm x 8,000mm) I.G. line in Beijing 2013. Now we are relentlessly moving forward, taking all challenges arisen ahead of us to become a global company.

Our mission is to help you make your business successful in long term by providing productive total solution for glass processing industry.