white fused alumina,brown fused alumina,alumina oxide,garnet sand,silicon carbide

For Price

Order(Bag)

Others /Others

Negotiate

Yes

FOB,EXW

L/C,T/T

25kg+1mt jumbo bags

2021/05/17

Place of Origin

south africa

Brand Name

SICHENG

Model Number

chromite

Product description:

Foundry chromite sand is a natural process products of chromite through the broken screen classification, chrome ore, its main chemical composition of cr2o3, this kind of sand heated volume stability, high thermal conductivity, when in contact information with the molten metal, not only has good resistance to basic slag, not with ferric oxide and other chemical reactions, and itself has the characteristics of the solid phase sintering, can be a very good prevent the infiltration of molten metal, avoid to touch sand defects, suitable for all kinds of stainless steel, alloy steel and carbon steel gradually shape the original sand core and coating.

Physical and chemical index:

Physics | Index | Chemistry | Index |

Bulk Density | 2.5-3g/cm? | Cr2O3 | ≥46.0% |

PH Value | 7-9 | SiO2 | ≤1.0% |

Cr/Fe | 1.55:1 | Fe2O3 | ≤26.5% |

Filling Density | 2.6 g/cm? | CaO | ≤0.30% |

Percent Moisture | ≤0.1 | MgO | ≤10% |

The sintered | 1600°C | AI2O3 | ≤15.5% |

Sintering Temperature | 2180°C | P | ≤0.003% |

Melting Point | >1800°C | C | ≤0.003% |

Regular size | |||

AFS 25-35 AFS25-30 AFS30-35 AFS35-40 AFS40-45 AFS45-50 AFS50-55 AFS55-60 AFS60-65 | |||

The production process:

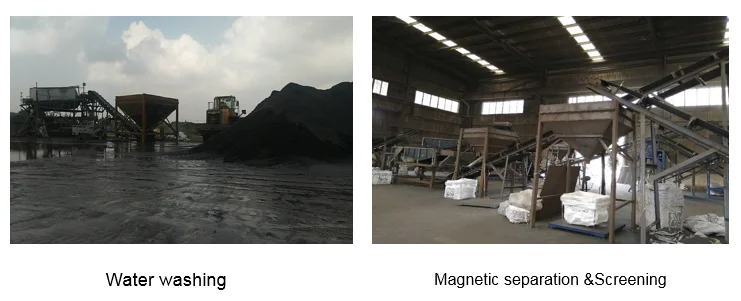

Step1: chrome ore raw material is processed by water washing.

Step2, drying raw materials to remove water;

Step3, drying raw materials into the vibrating screen, screening out the size of the customer needs;

Step4, the size of the sieve for magnetic separation, the purpose of iron and silicon removal. After magnetic separation, the chromium content reached more than 46% and the silicon content was less than 1%.

Step5: package the finished product.

Why choose us:

1. We are a manufacturer, which can control the cost easier than trade company also can give you answer more quickly.

2. As a manufacturer, we know much in technique and can give you more support in technique problem.

3. Professional and experienced service team, specialized in abrasive production ,more than 10 years.

4.Our products are complete in specifications with various of sizes.

5. We enjoy a good reputation in the customers in domestic and overseas markets.

6. Large production capacity, short lead time of products.

7. 24*7 online service.

If you have another question, pls feel free to send us the inquiry:

Henan-China

Manufacturer

white fused alumina,brown fused alumina,alumina oxide,garnet sand,silicon carbide

Tel:

Fax:86-

China

China

China