Tempered Glass ,Float Glass ,Custom Cover Glass,ITO Conductive Glass ,FTO Conductive Glass ,Mirror Glass ,Quartz Glass ,Switch Top Glass Panel

For Price

Order()

Flat Glass/Ultra-Thin Glass

Negotiate

Yes

FOB,EXW,CIF

T/T,Paypal,Others

Protective film package

2020/11/10

Thickness

1.1mm

Mohs rating

19

Density

2.5g/cm^3

Transmittance

91%

Purity

18%

Heat resistance

180°C

Melting point

712℃

Colour

Clear

Technique

Cutting-Polishing-Tempering-Silkscreen Printing-Packing

Brand Name

Saida Glass

Model Number

M1

Shape

Can be customized

OEM

23

Production Description

Silk-sreened glass, also called silk printing or screened printing glass, is custom-made by transferring a silk-screen image to the glass and then processing it through a horizontal tempering furnace. Each individual lite is screen-printed with the desired pattern and ceramic enamel frit color. The ceramic frit can be silk-screened onto the glass substrate in one of three standard patterns–dots, lines, holes–or in a full-coverage application. In addition, custom patterns can be easily duplicated on the glass. Depending on the pattern and the color, the glass lite can be made transparent, translucent or opaque.

Chemically strengthened glass is a type of glass that has increased strength as a result of a post-production chemical process. When broken, it still shatters in long pointed splinters similar to float glass. For this reason, it is not considered a safety glass and must be laminated if a safety glass is required. However, chemically strengthened glass is typically six to eight times the strength of float glass.

The glass is chemically strengthened by a surface finishing process. Glass is submersed in a bath containing a potassium salt (typically potassium nitrate) at 300 °C (572 °F). This causes sodium ions in the glass surface to be replaced by potassium ions from the bath solution.

These potassium ions are larger than the sodium ions and therefore wedge into the gaps left by the smaller sodium ions when they migrate to the potassium nitrate solution. This replacement of ions causes the surface of the glass to be in a state of compression and the core in compensating tension. The surface compression of chemically strengthened glass may reach up to 690 MPa.

Material: clear, extra clear, low iron glass

Thickness: 0.7/1.1/2/3mm

Size: customized

Shape: round, rectangular, irregular

Tempering: more than 50 particles in 50x50mm area

Printing: clear, white, black, or according to pantone card

Packing: double side protective film, then wraped by kraft paper, then in polywood case

Product Name | Customzied 10inch Black Printed Glass Front Cover Glass for Car Navigation |

| Material | Soda Lime Glass/Low Iron Glass |

| Color | Can be customized |

| Size | 3-100inch |

| Shape | Round/Square/Rectangle/Can be customzied |

| Thickness | 0.55-12mm |

| Production Procedures | Cutting-Polishing-Chemical Tempering-Silkscreen Printing-Cleaning-Packing |

| Function | Waterproof/Anti-Scratches/Impact Resistance/Super Flatness |

Chemically strengthened glass is a type of glass that has increased strength as a result of a post-production chemical process. When broken, it still shatters in long pointed splinters similar to float glass. For this reason, it is not considered a safety glass and must be laminated if a safety glass is required. However, chemically strengthened glass is typically six to eight times the strength of float glass.

The glass is chemically strengthened by a surface finishing process. Glass is submersed in a bath containing a potassium salt (typically potassium nitrate) at 300 °C (572 °F). This causes sodium ions in the glass surface to be replaced by potassium ions from the bath solution.

These potassium ions are larger than the sodium ions and therefore wedge into the gaps left by the smaller sodium ions when they migrate to the potassium nitrate solution. This replacement of ions causes the surface of the glass to be in a state of compression and the core in compensating tension. The surface compression of chemically strengthened glass may reach up to 690 MPa.

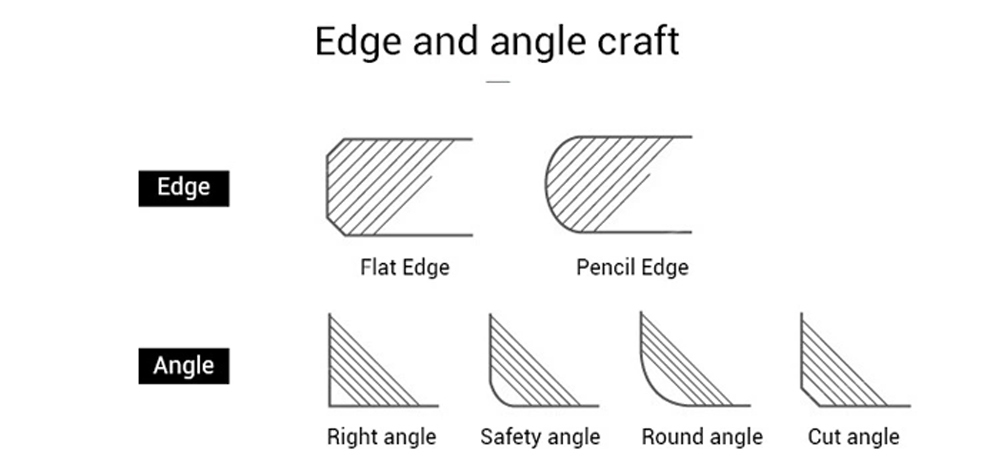

Edge & Angle & Shape Work

Equipment Resources

Saida Glass was founded in 2011, which is located in Dongguan, near to Shenzhen and Guangzhou port. With over Ten years' experience in glass deep processing, specialized in customized glass, we work with many large-scale global enterprises such as Lenovo, HP, TCL, Sony, Glanz, Gree, CAT and other companies. We have 3,500 square meters production base, 30 R&D staff with twelve years' experience, 120 QA staff with seven years' experience. Our products passed ASTMC1048 (the US), EN12150 (EU), AS/NZ2208 (AU) and CAN/CGSB-12.1-M90 (CA). Thus, 98% of customer are satisfined with our one-stop services. We have been engaged in export for seven years. Our major export markets are North America, Europe, Oceania and Asia. We are offering glass deep processing services to SEB, FLEX, Kohler, Fitbit and Tefal. Work with Large-scale Companies Saida Glass was founded in 2011, which is located in Dongguan, near to Shenzhen port and Guangzhou port. With over seven years' experience in glass processing, specialized in customized glass, we work with many large-scale enterprises such as Lenovo, HP, TCL, Sony, Glanz, Gree, CAT and other companies. Wide Product Range to Choose From - Optical capacitive touch screen glass panels - Screen protective glass panels - Tempered glass panels of household appliances and industrial equipment. - Glass panels with surface treatment

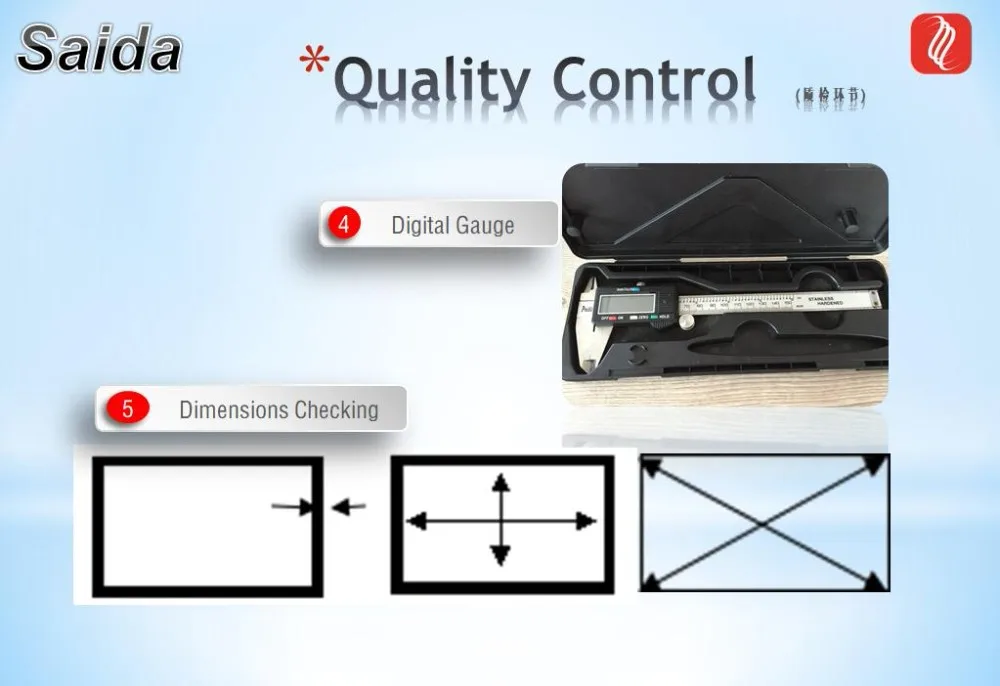

Quality Inspection

FAQ

Q: Are you a trading company or manufacturer?

A: 1. a leading glass deep processing factory

2. 10 years experience

3. profession in OEM

4. founded 3 factories

Q:How to order? Contact our salesperson below or right instant chat tools

A: 1.your detailed requirements:drawing/quantity/ or your sepcial requirments

2. Know more about each other: your request ,we can provide

3. Email us your official order, and send deposit.

4. We put the order into mass production schedule, and produce it as per the approved samples.

5. Process balance payment and advise us your opinion on safe delivery.

Q:Do you offer samples for testing?

A:We can offer free samples, but freight cost would be customers side.

Q:What’s your MOQ?

A:500pieces.

Q:How long a sample order takes?How about bulk order?

A:Sample order: normally within one week,

Bulk order:usually takes 20 days according to quantities and design.

Q:What package do you use for products?

A:Plastic paper+pearl cotton+kraft paper+cartoon box+wood case.

Q:How do you ship the goods and how long does it take to arrive?

A:We usually ship the goods by sea/air and the arrival time depends on the distance.

Q:What is your payment terms?

A:T/T 30% deposit, 70% before shipping or other payment method.

Q:Do you provide OEM service?

A:Yes, we can customize acordingly.

Q:Do you have certificates for your products?

A:Yes,we have ISO9001/REACH/RoSH Certifications.

Guangdong-China

ManufacturerTrader

Tempered Glass ,Float Glass ,Custom Cover Glass,ITO Conductive Glass ,FTO Conductive Glass ,Mirror Glass ,Quartz Glass ,Switch Top Glass Panel

Tel:+13580886639

Fax:86-

China

China

China

China