sputtering,vacuum coating,magnetron sputtering,reflect glass,coated glass,mirror,Low-E glass,ITO

For Price

Order(Bag)

Glass Machine & Equipment/Coated Glass Line

Negotiate

Yes

CIF

L/C,T/T

None

2020/11/16

Condition

Customized made

Place of Origin

China

Machine Type

Sputter Glass Coating Line

Production Capacity

1-2 million SQM per year

Brand Name

GVAC

Model Number

MSGC-2540

Processable glass type

float glass

Sputtering Coating Procedure

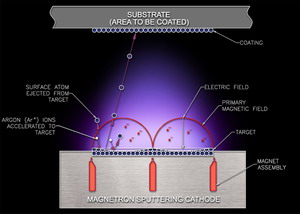

Sputtering is a vacuum evaporation process which physically removes portions of a coating material called the target, and deposits a thin, firmly bonded film onto an adjacent surface called the substrate. The process occurs by bombarding the surface of the sputtering target with gaseous ions under high voltage acceleration. As these ions collide with the target, atoms or occasionally entire molecules of the target material are ejected and propelled against the substrate, where they form a very tight bond.

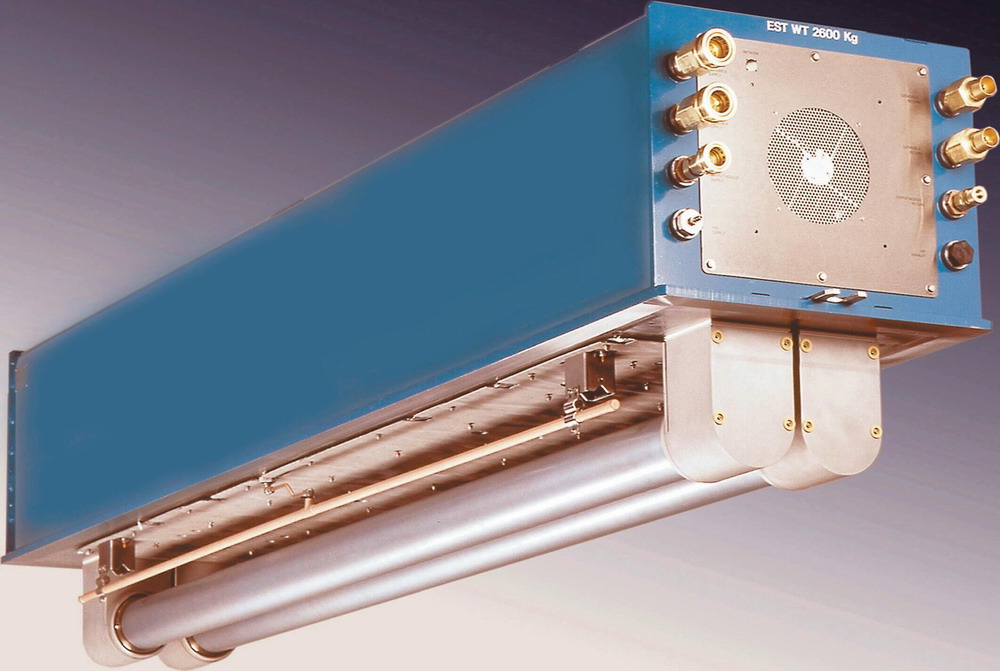

Magnetron Sputtering Cathode

Equipped with rectangular Magnetron Sputtering Cathode with lasting magnet on the back, to ensure the magnetic line of force penetrate the target, and form a rectangular enclosed annular magnetic field that perpendicular to the electric field on the surface of the target. In this procedure, electrons do trochoidal motion in this crossed electric and magnetic field, to increase the ionizing rate of the gas, density of ions as well as sputtering rate. Meanwhile, reduce the temperature of glass substrate.

Compared to planar targets, rotary targets generally have more surface area per given length. Rotary targets have much more surface area, so the magnetron power can be spread out over a larger area in a given amount of time. This helps keep the target running cooler, decreases nodule formation, and reduces the occurrence of arcing.

1. Since rotary sputtering decreases nodule formation, targets can have longer continuous runtimes.

2. There is generally more material available to sputter on a rotary target, which increases runtimes.

3. Rotary target utilization is usually ~80%, as opposed to ~30% for planar targets – which decreases scrap and increases runtimes.

4. Rotary targets are more cost effective for high volume processes. They provide a good platform for long runtime processes, with less chance of defects and downtime.

Sichuan-China

Manufacturer

sputtering,vacuum coating,magnetron sputtering,reflect glass,coated glass,mirror,Low-E glass,ITO

Tel:0086-28-87086858-811

Fax:0086-2887086861

China

China