sputtering,vacuum coating,magnetron sputtering,reflect glass,coated glass,mirror,Low-E glass,ITO

For Price

Order(Bag)

Glass Machine & Equipment/Coated Glass Line

Negotiate

Yes

FOB,CIF

L/C,T/T

None

2020/11/26

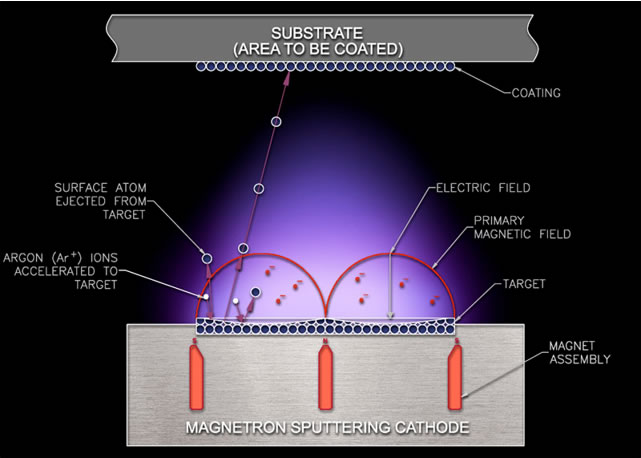

Sputtering Coating Procedure

Sputtering is a vacuum evaporation process which physically removes portions of a coating material called the target, and deposits a thin, firmly bonded film onto an adjacent surface called the substrate. The process occurs by bombarding the surface of the sputtering target with gaseous ions under high voltage acceleration. As these ions collide with the target, atoms or occasionally entire molecules of the target material are ejected and propelled against the substrate, where they form a very tight bond.

DC Sputtering Cathode

The coating machine equipped with a rectangular DC Magnetron Sputtering Cathode. The high quality magnet with the permanent magnetic filed installed at the back of the target, when the magnetic line of force penetrate through the target, a rectangular closed magnetic field which is perpendicular to the electric field will be formed. The electron is moving in this electric-magnetic field restricted on a cycloid track. This moving could increase the gas ionizing rate and density of ions, resulting the higher sputtering rate. In other hand, since the electron has been regulated, so the secondary electron is infrequently impacted the substrate, then could keep the substrate in a low temperature.

Sichuan-China

Manufacturer

sputtering,vacuum coating,magnetron sputtering,reflect glass,coated glass,mirror,Low-E glass,ITO

Tel:0086-28-87086858-811

Fax:0086-2887086861

China

China