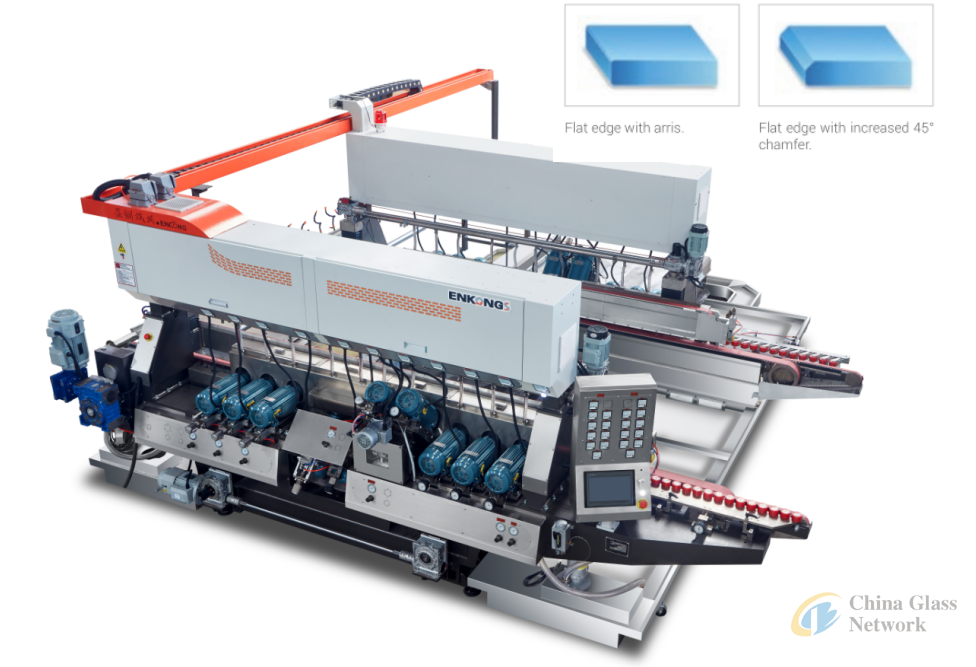

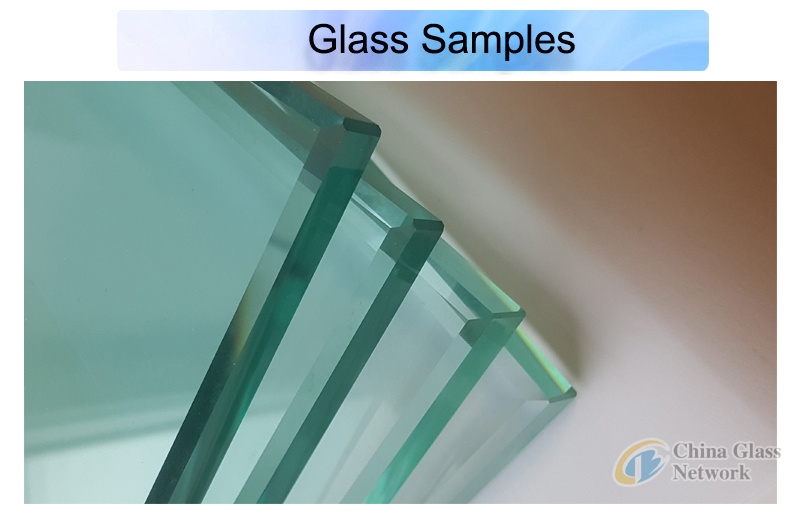

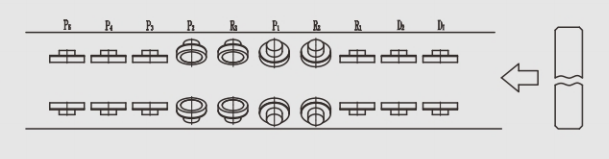

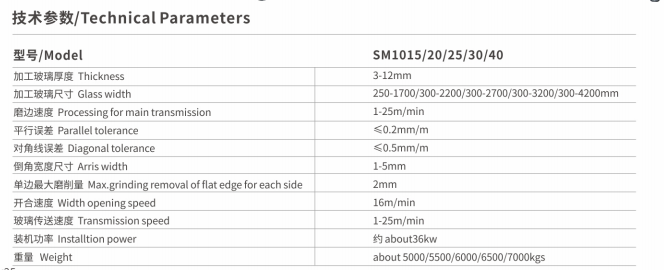

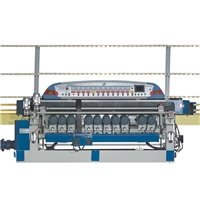

glass automatic high speed polishing double straight-line edging machine,standard double edging machine,glass doubels side seaming edging machine,double pencil edging machine,high-tech double pencil edging machine,glass straight line edging machine,glass flat edging,glass straight line beveling machine