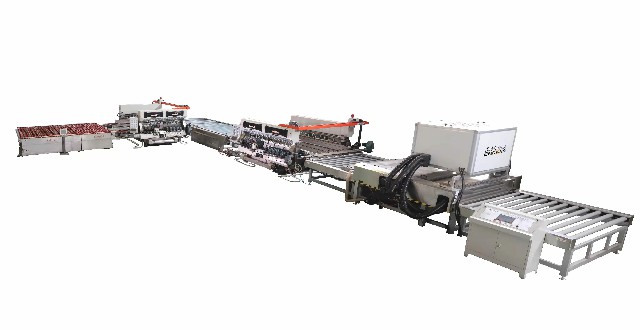

General description:

1、SM24 adopted to auto-polish feeding senor, optimizing polish level

2、Suitable for high polish demanded products, such as household appliances and furniture.

3、Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within ±0.5mm in 1m^2.

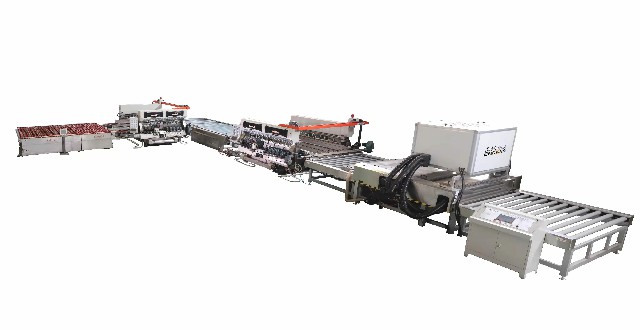

The edging production line is beginning on 1# edging machine, and the transfer table is automatically turned to the long side of the 2# grinding machine. The processing speed is 1-15m/min.

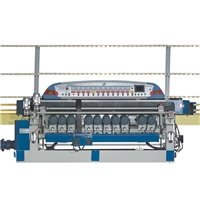

PLC control system to set the processing parameters through the monitor interface to complete the processing at one time. The stable and solid base structure contribute to precise and fast width adjustment system. The main transmission adopted timing belt (Italian branded) and is equipped with variable frequency motor speed control. Under modular design concept, the double straight edge machine can be equipped with enhanced polishing and low e deletion devices. The polishing spindles can be selected pneumatic polishing or automatic feeding polish which improving the polishing quality and reduce the labor intensity of workers. Safety feature such as safety rope protection mechanism can be find in the machine to protect the operator and maintenance personnel. The whole line has compact structure, stable and reliable performance, high degree of automation, and high production efficiency. It is the great supporting machine for large-scale furniture and architectural decoration glass processing. It can be paired with production lines such as lamination, printing and tempering.

Technical Data:

Number of Spindles: 24

Max. glass dimension: Up to 4200(option: Jumbo Glass Size can be customize)

Min. glass size: 300x300 (option: 250x250)

Glass thickness: 3~25 mm

Working Speed: 1-15m/min

Width adjustment Speed: 4m/min (optional:8m/min)

Max. edge grinding: 3mm

Tolerance of the diagonal(1000x1000): ±0.5mm

Tolerance on the parallelism(mm): ±0.2mm

Arris width:1-5mm

Total power: about 65KW

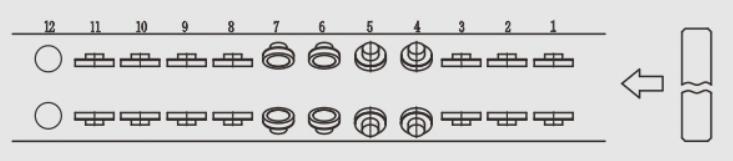

|

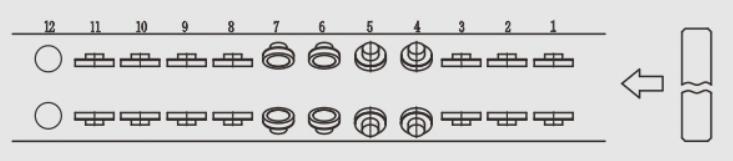

Position No.1 (flat edge) | D175×D12 | Diamond wheel |

Position No.2 (flat edge) | D175×D12 | Diamond wheel |

Position No.3 (flat edge) | D175×D12 | Resin wheel |

Position No.4 (upper arris) | D150 ×D12 | Resin wheel |

Position No.5 (upper arris) | D150 ×D70x30 | Tipping wheel |

Position No.6 (down arris) | D150 ×D12 | Resin wheel |

Position No.7(down arris) | D150 ×D70x30 | Tipping wheel |

Position No.8 (flat edge) | D150 ×D70x30 | Tipping wheel |

Position No.9 (flat edge) | D150 x D70X30 | Tipping wheel |

Position No.10 (flat edge) | D150 x D70X30 | Tipping wheel |

Position No.11 (flat edge) optional | D150 x D70X30 | Tipping wheel |

Position No.12 (flat edge) optional | D150 x D70X30 | Low E Deletion |