Insulating glass production machine,aluminum spacer bender,Butyl coating machine,Glass cutting machine,tempering glass machine,automatic desiccant filling machine,IR interactive whiteboard,water pump

For Price

Order(Set)

$52000

1

Glass Machine & Equipment/Hollow Glass Line

Negotiate

No

FOB,EXW,CFR,CIF

T/T

Simple package

2021/11/16

Condition

New

Place of Origin

China

Machine Type

Insulating glass production line

Production Capacity

1000 square meters per day

Brand Name

BOKE

Model Number

LBP1800Q

Voltage

380V

Power

33W

Dimension(L*W*H)

19720*2200*2850mm*mm*mm

Weight

7800kg

After-sales Service Provided

12 Months for Free, Lifetime Warranty

Glass thickness

3-15mm

Processable glass type

Float glass, coated glass, tempered glass, liminated glass

Type

glass processing machine

Model

LBP1800Q

Min size

450*200mm

Working speed

15-45m/min

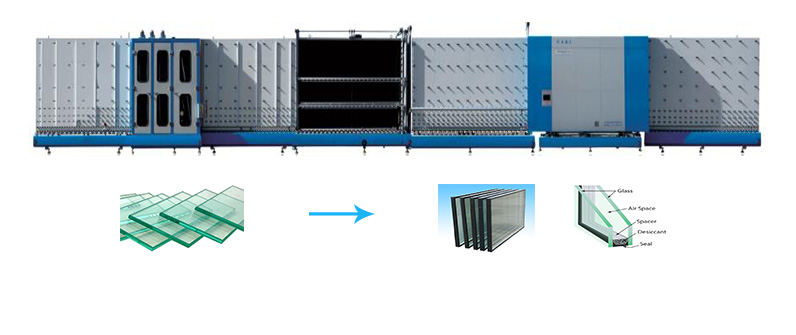

2500*1800mm Insulating Glass Production Line with Gas Filling Online

1. Brief introduction of LBP1800Q insulating glass production line with gas filling on line

This Vertical Insulating glass machine is composed of

1) loading section,

2) washing and drying section,

3) transmission and storage section,

4) light inspection and spacer bar attaching section,

5) transmission and out-panel aseembly section,

6) inner-panel assembly and inert gas filling section,

7)storage and unloading section.

This line is controlled by PLC and realizes the automatic control and frequency control of the motor speed of the whole line.

The gas filling section adopts servo motor to control glass positioning, bracket movement and sponge roll loosening, which is convenient to operate, accurate positioning and reliable movement.

There are two operation methods in the control panel 'automatic' and 'manual'.

2. Performance characteristic for Insulating Glass Production Line:

1) Automatically distinguish the coating side of coated glass and Low-E glass, indicated by alarm.

2) Static state put glass when load glass sheet

3) The washing machine adopts stainless steel and other corrosion resistant material

4) Three pair of soft brushes, which can wash Low-E glass and won't break the coating.

5) Can process 3~18mm thickness glass sheet

6) It can process same edge double layers and triple layers insulating glass

7) Adopt low-voltage electric apparatus component, the sensor, PLC, whole process automatically control machinery.

8) Treat the surface of plate guard through baking, powder coated

9) The dry part use circulation hot wind

10) The press section can be opened in large journey to maximum 500mm, easy to maintenance

11) The inert gas filling efficiency is more than 95%.

12) PLC control system with touch screen interface

13) Glass position memory function

3. Insualting Glass Production Line with Argon Gas Filling on line Technical Data and Specification

| Model | LBP1800Q |

| Max processing glass size | 1800*2500mm |

| Min processing glass size | 450*200mm |

| Single glass thickness | 3-15mm |

| Cleanout speed | 3-10m/min |

| Work speed | 15-45m/min |

| Power supply | 3P. 380V/50Hz |

| Total power | 33Kw (include heater 10Kw) |

| Inert gas type | Argon, Nitrogen, etc. |

| Inert gas efficiency | More than 85% |

| Total weight | 7800Kg |

| Outline Dimension | 19720*2200*2850mm |

4. Detailes Photos of Insulating Glass Production Machine

Shandong-China

Trader

Insulating glass production machine,aluminum spacer bender,Butyl coating machine,Glass cutting machine,tempering glass machine,automatic desiccant filling machine,IR interactive whiteboard,water pump

Tel:

Fax:86-