construction material,equipment,Glass engineering design,Glass engineering construction,technical service

For Price

Order(Bag)

Others /Others

Negotiate

No

FOB,EXW,CIF

L/C,T/T,D/P,Paypal

None

2023/01/06

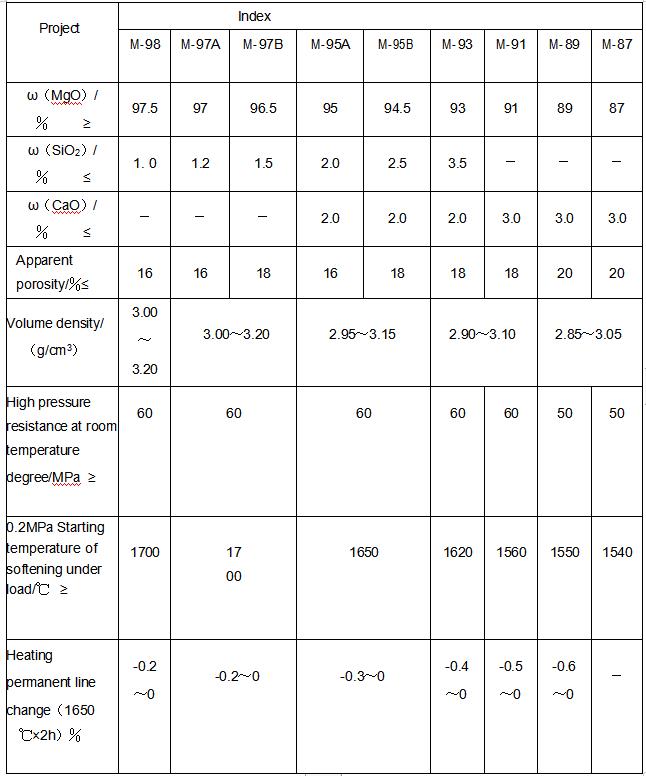

Magnesite is the main raw material of magnesia brick, and its basic component is MgCO3, which is calcined at high temperature and then crushed to a certain particle size to become sintered magnesia. Magnesia is widely used as furnace mending material and ramming material. Magnesia with few impurities (ω(CaO)<2.5%, ω(SiO2)<3.5%) is used as raw material for manufacturing magnesia bricks.

Magnesia brick belongs to basic refractory, which has strong resistance to alkaline slag, but can't resist the erosion of acidic slag. At 1600℃, it can react with silica brick, clay brick and even high alumina brick. The fire resistance of magnesium brick is above 2000℃, but its softening point under load is only 1500~1550℃. Moreover, the temperature interval from softening to 40% deformation is very small, and the thermal stability of magnesia brick is poor only at 30~50℃, which is an important reason for the damage of magnesia brick.

In heating furnace and soaking pit, magnesia brick is mainly used to pave the bottom surface layer and the bottom wall of soaking pit, which can resist the erosion of iron oxide scale.

Production technology:

Magnesia raw materials are crushed into granular materials and powder materials. After proportioning according to a certain ratio, they are mixed with binder to form pug, and then the fired magnesia brick is made by molding, drying and firing. The firing temperature of ordinary magnesia brick is generally 1500~1650℃, while that of high purity magnesia brick is as high as 1700~1900℃. The production process of chemical bonded magnesia brick is basically the same, except that it can be made into unfired magnesia brick by chemical bonding agent without high-temperature firing, and only by proper low-temperature heat treatment.

Nanjing Baisheng Glass Technology Co., Ltd. and Nanjing Baisheng Equipment Technology Co., Ltd. were established in 2007 and 2013 respectively. Located in the Airport Science & Technology Industrial Park, Lishui District, Nanjing, the company is a global glass technology equipment engineering system integration service provider,supplying "one-stop" system integration services including glass engineering R & D, engineering construction, equipment manufacturing, commissioning and production and operation. Since its establishment, the company has always adhered to the purpose of "Science & Technology, Innovation and Service" to create value for customers.

Jiangsu-China

ManufacturerServiceOrganization

Business License

construction material,equipment,Glass engineering design,Glass engineering construction,technical service

Tel:18905143366

Fax:86-02552445152

China

China

China