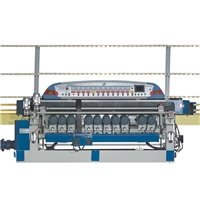

Fully Automatic C-Edge Glass Grinding Machine

The Fully Automatic C-Edge Double Edger represents the pinnacle of automation and precision in glass edge processing. Designed for deep cold processing of solar glass, home appliance glass, and furniture glass, this cutting-edge machine is equipped with an automatic tool changer that facilitates seamless, fully automated grinding wheel exchanges. With up to 4 different glass thickness grooves per grinding wheel, it ensures precise and consistent edge finishes for a wide range of glass thicknesses, while minimizing manual intervention and downtime.

The machine features advanced robotic technology that ensures accurate alignment, automatic calibration, and efficient transitions between different stages of processing. With the ability to integrate 4 to 8 grinding spindles and a built-in polishing function, it guarantees smooth and flawless edge finishes. An optional corner cutting station further enhances its versatility, making it an ideal solution for a variety of glass applications.

To further boost efficiency, the Fully Automatic C-Edge Glass Edging Machine incorporates energy-efficient features, and even can be optionally equipped with permanent magnet motors that optimize performance while minimizing power consumption. Additionally, a centralized process control station allows for seamless operation across multiple machines, offering real-time monitoring and automatic adjustments for glass size control, grinding parameters, and more.

Key Features:

Automatic Tool Changer: Facilitates automatic exchange of grinding wheels, with up to 4 different grooves per wheel, minimizing manual handling and downtime.

Robotic Technology Integration: Ensures precise transitions, automatic alignment, and calibration, reducing the need for human intervention and enhancing overall process efficiency.

Multiple Grinding Spindles & Polishing: Configurable with 4 to 8 grinding spindles, with built-in polishing function for superior glass edge finishes.

Energy-Efficient Performance: Equipped with energy-saving functions and permanent magnet motors (optional) that optimize energy use, providing high performance with minimal power consumption.

Corner Cutting Station (Optional): Expand the machine’s capabilities with an optional corner cutting station for precise corner processing.

Centralized Process Control: Offers real-time monitoring of key parameters such as glass size, grinding parameter adjustments, and low-energy operation mode for optimal performance.

Process Water Control: Integrated automatic cleaning system for cooling pipes with real-time water pressure control, ensuring smooth and consistent operation.

Specifications:

Speed: 0 to 18 m/min

Glass Thickness: 2mm to 8mm

Minimal Glass Size: 150mm (W) x 100mm (L) grinding; 300mm (W) x 250mm (L) corner cutting

Maximal Glass Size: 3600mm (W) x 2500mm (L)

Size Tolerance: ±0.2mm

Diagonal Tolerance: ±0.5mm/m

Note: The specifications provided are standard reference values. The Fully Automatic C-Edge Glass Grinding & Polishing Machine can be customized to meet your specific production needs.

Why Choose Fully Automatic C-Edge Glass Grinding Machine?

Enhanced Automation: With features like automatic tool changing, robotic alignment, and automatic calibration, this machine minimizes manual intervention, reducing downtime and increasing throughput.

Precision & Consistency: The machine delivers high-precision glass edge processing with minimal size and diagonal tolerances, ensuring flawless edge finishes for both thin and large-format glass sheets.

Real-Time Monitoring: The centralized process control station offers full control over critical process parameters, enabling efficient production management and real-time adjustments.

The Fully Automatic C-Edge Glass Edging Machine offers a complete solution for high-efficiency glass edge grinding and polishing, combining advanced robotics, automation, and energy efficiency. Perfect for high-volume production of solar glass, home appliance glass, and furniture glass, this machine guarantees superior edge finishes and optimized production performance.